Nickel Alloy Inconel X-750 UNS N07750

HY X-750 Material grades and equivalents

Inconel X-750 / GB GH4145 / UNS N07750/W.Nr.2.4669 NiCr15Fe7TiAl / AFNOR NC15FeT

HY X-750 Chemical composition:

|

Alloy |

% |

Ni |

Cr |

Fe |

Nb |

Co |

C |

Mn |

Si |

S |

Cu |

Al |

Ti |

|

HY X-750 |

Min. |

14 |

5 |

0.7 |

0.4 |

2.25 |

|||||||

|

Max. |

70 |

17 |

9 |

1.2 |

1 |

0.08 |

1 |

0.5 |

0.01 |

0.5 |

1 |

2.75 |

HY X-750 Physical properties:

|

Density |

8.28 g/cm3 |

|

Melting range |

1393-1427℃ |

HY X-750 Alloy m inimum Mechanical properties in the room temperature:

|

Alloy |

Tensile strength |

Yield strength RP0.2N/mm2 |

ElongationA5 % |

Brinell hardness HB |

|

Solution treatment |

1267 |

868 |

25 |

≤400 |

HY X-750 Characteristic as below::

HY X-750 is a precipitation-hardenable alloy which has been used in applications such as high temperature structural members for gas turbines, jet engine parts, nuclear power plant applications, heat-treating fixtures, forming tools, and extrusion dies. The alloy is highly resistant to chemical corrosion and oxidation and has high stress-rupture strength and low creep rates under high stresses at temperatures up to 1500°F (816°C) after suitable heat treatment.

HY X-750 Machinability:

Conventional machining techniques used for iron based alloys may be used. This alloy does work-harden during machining and has higher strength and “gumminess” not typical of steels. Heavy duty machining equipment and tooling should be used to minimize chatter or work-hardening of the alloy ahead of the cutting.

HY X-750 Corrosion resistance:

HY X-750 has excellent resistance to chloride ion stress-corrosion cracking. It exhibits satisfactory resistance to numerous oxidizing environments. The alloy has similar corrosion resistance to alloy 600 in many media.

HY X-750 Application range and field:

- Nuclear reactors

- Gas turbines

- Rocket engines

- Pressure vessels

Specifications:

|

Plate |

AMS 5542/ASM 5598/Mil-N-7786 |

|

Forgings |

AMS 5667/AMS 5668/AMS 5669/AMS 5670/AMS 5747/AMS B-637 |

Aircraft structures

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

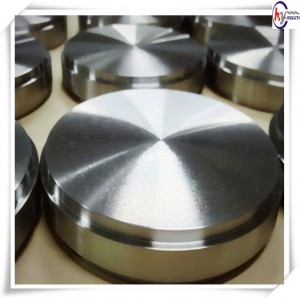

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |