Nickel Alloy Hastelloy C-4 UNS N06455

HY HC-4 Chemical compostion:

|

Alloy |

% |

Ni |

Cr |

Mo |

Fe |

C |

Mn |

Si |

Co |

S |

P |

Ti |

|

C-4 |

Min. |

65 |

14 |

14 |

||||||||

|

Max. |

18 |

17 |

3 |

0.01 |

1 |

0.08 |

2 |

0.01 |

0.025 |

0.7 |

HY HC-4 Physical properties:

|

Density |

8.64 g/cm3 |

|

Melting point |

1350-1400 ℃ |

HY HC-4 Alloy minimum mechanical properties in the room temperature:

|

Alloy |

Tensile strength |

Yield strength |

Elongation |

|

C-4 |

783 |

365 |

55 |

HY HC-4 alloy is a nickel-chromium-molybdenum alloy with outstanding

high-temperature stability as evidenced by high ductility and corrosion resistance even after aging in the 1200 to 1900°F (649 to 1038°C) range. This alloy resists the formation of grain-boundary precipitates in the weld heat-affected zone, thus making it suitable for most chemical process applications in the as-welded condition. C-4 alloy also has excellent resistance to stress-corrosion cracking and to oxidizing atmospheres up to 1900°F (1038°C).

HY HC-4alloy has exceptional resistance to wide variety of chemical process environments. These include hot contaminated mineral acids, solvents, chlorine and chlorine contaminated media (organic and inorganic), dry chlorine, formic and acetic acids, acetic anhydride, and seawater and brine solutions.

HY HC-4alloy can be forged, hot-upset, and impact extruded. Although the

alloy tends to work-harden, it can be successfully deep-drawn, spun, press formed or punched. All of the common methods of welding can be used to weld HASTELLOY C-4 alloy, although the oxy-acetylene and submerged arc processes are not recommended when the fabricated item is intended for use in corrosion service. Special precautions should be taken to avoid excessive heat input.

Specifications:

|

Sheet, Plate & Strip |

SB 575/B 575(P= 43) |

|

Billet, Rod & Bar |

SB 574/B 574(P= 43) |

|

Bare Welding Rods & Wire |

SFA 5.14/ A 5.14(ERNiCrMo-7)DIN 2.4611(SG-NiMo16Cr16Ti)(F= 43) |

|

Seamless Pipe & Tube |

SB 622/B 622(P= 43) |

|

Welded Pipe & Tube |

SB 619/B 619;SB 626/B 626(P= 43) |

|

Fittings |

SB 366/B 366(P= 43) |

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

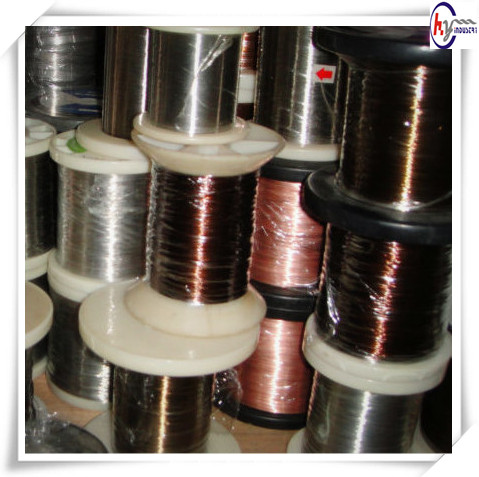

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |