Nickel Alloy Incoloy A-286 UNS S66286

HY A-286 Chemical composition:

|

Alloy |

% |

Ni |

Cr |

Mo |

B |

Fe |

Al |

Ti |

C |

Mn |

Si |

V |

S |

|

HY A-286 |

Min. |

24 |

13.5 |

1.0 |

0.001 |

1.9 |

0.1 |

||||||

|

Max. |

27 |

16 |

1.5 |

0.01 |

Balance |

0.35 |

2.35 |

0.08 |

2.0 |

1.0 |

0.5 |

0.03 |

HY A-286 Physical properties:

|

Density |

7.93 g/cm3 |

|

Melting point |

1364-1424℃ |

HY A-286 minimum mechanical properties in the room temperature:

|

Status |

Tensile strength |

Yield strength |

Elongation |

|

HY A-286 |

950 |

680 |

28 |

An alloy that is precipitation hardenable for high mechanical properties. The alloy maintains good strength and oxidation resistance at temperatures up to about 1300°F (700°C). The alloy’s high strength and excellent fabrication characteristics make it useful for various components of aircraft and industrial gas turbines. Applications include blades, vanes, shafts, tail cones, afterburners, springs, and fasteners. This alloy is also used for automotive applications.

Specifications:

|

Rod, Bar, Wire and Forging Stock |

ASTM A 638;ASME SA 638;SAE AMS 5726;SAE AMS 5731;SAE AMS 5732;SAE AMS 5734;SAE AMS 5737;SAE AMS 5895;BS HR 51;BS HR 52;AECMA PrEn2171;AECMA PrEN2119;AECMA PrEN2172;AECMA PrEN2173;AECMA PrEN2174;AECMA PrEN2303;AECMA PrEN2304;AECMA PrEN2398;AECMA PrEN2399;AECMA PrEN3510 |

|

Plate, Sheet and Strip |

SAE AMS 5525;SAE AMS 5858;AECMA PrEN2175;AECMA PrEN241 |

|

Pipe & Tube |

SAE AMS 5731;SAE AMS 5732;SAE AMS 5734;SAE AMS 5737;SAE AMS 5895 |

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

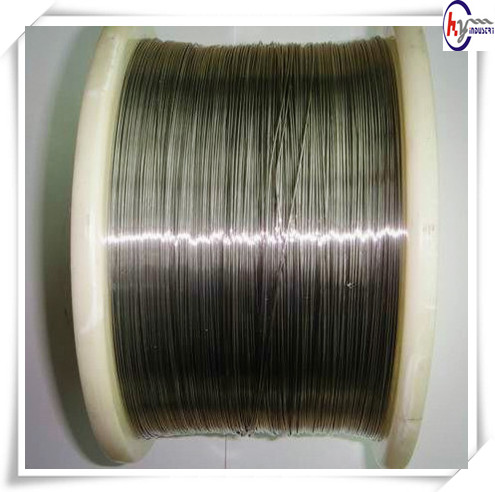

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

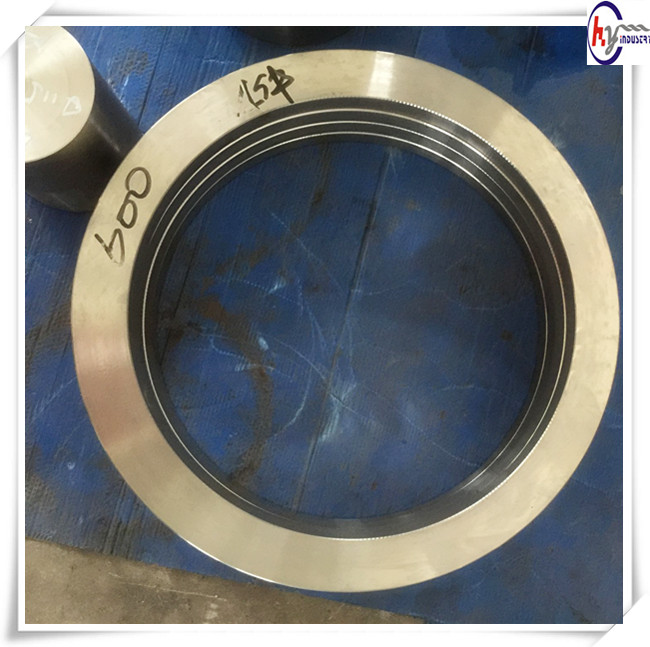

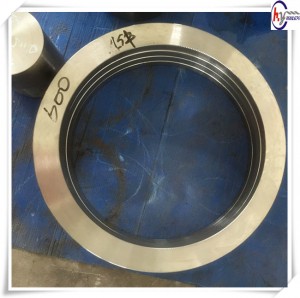

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |