Nickel Alloy Inconel 600 UNS N06600

HY 600 Material grades and equivalents

HY 600 Inconel 600/ GB NS312 / UNS N06600 / SEW VDIUV W.Nr.2.4816 NiCrl 5Fe/ BS NA14 / AFNOR NC15FE

HY 600 Chemical composition:

|

Alloy |

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

Cu |

P |

S |

|

600 |

Min. |

72 |

14 |

6 |

||||||

|

Max. |

17 |

10 |

0.15 |

1 |

0.5 |

0.5 |

0.015 |

0.015 |

HY 600 Physical properties:

|

Density |

8.4 g/cm³ |

|

Melting Point |

1370-1425 ℃ |

HY 600 Alloy m inimum Mechanical properties in the room temperature:

|

Aolly status |

Tensile strength |

Yield strength |

Elongation |

Brinell hardness |

|

Rm N/mm² |

R P 0. 2N/mm² |

A 5 % |

HB |

|

|

Annealing treatment |

550 |

240 |

30 |

≤195 |

|

Solution treatment |

500 |

180 |

35 |

≤185 |

HY 600 Characteristic as below:

1.Good corrosion resistance property for the reduction, oxidation, Nitric and other media. 2.Good stress corrosion cracking resistance property in both room temperature and high temperature.

3.Good corrosion resistance of the dry chlorine and chlorine hydride.

4.Good mechanical property when below zero, room temperature and high temperature.

5.Good anti-creep rupture strength, with the recommendation of 700℃ or above working environment.

HY 600 Metallurgical structure

600 is face-centered cubic lattice structure.

HY 600 Corrosion resistance

600 have corrosion resistance to many kinds of corrosive media. Chromium content made it with better corrosion resistance than Nickel 99.2 (alloy200) and Nickel 99.2 ( alloy201,low carbon) in the oxidize environment. Meantime, high Nickel content make this alloy with good corrosion resistance in the reduction condition and alkaline solution, and also effective avoid chlorine-iron stress corrosion cracking. 600 have good corrosion resistance in the acid, acetic acid, formic acid, stearic acid and other organic acid, with medium corrosion resistance in the inorganic acid. The alloy with excellent corrosion resistance in the first and the second recycling use of the high purity water in the nuclear reactor. Especially excellent corrosion resistance to dry chlorine and chlorine hydride applied up to 650 ℃. When nder the high temperature, annealing and state solution alloy have good antioxidant off and high-intensity in the air, 600 can resist the ammonia, nitriding and carburizing atmosphere, but at the turn of the changes in redox conditions, it will be corrosion by parts of oxidation media.( such as green death liquid)

HY 600 Application field:

1. Erosion thermocouple sheath of the atmosphere

2.Vinyl chloride monomer production: corrosion resistance to chlorine, hydrogen chloride, oxidation and carbonation.

3. Oxide shaft chloride converted to six fluoride: hydrogen fluoride anti-corrosion.

4. Corrosive alkali metal produce and usage filed, especially the sulfide use environment.

5. Use Chlorine produce titanium dioxide

6.Organic or inorganic chlorine produce: corrosion resistance to chlorine and fluoride.

7. Nuclear reactor

8.Heat treatment furnace flask and components, especially in the carbonization and nitride atmosphere.

9. Petrochemical works production of catalytic regeneration in the application of more than 700℃ recommended the use of 600, in order to obtain a longer service life.

Specifications:

|

Tube/pipe Smls |

Tube/Pipe Welded |

Sheet/Plate |

Bar |

Forging |

Fitting |

|

B167/ B163 |

B517/ B516 |

B168 |

B166 |

B564 |

B366

|

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

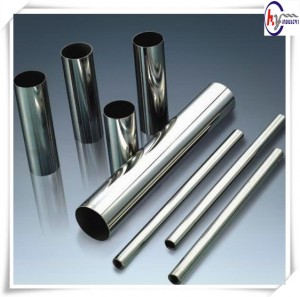

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

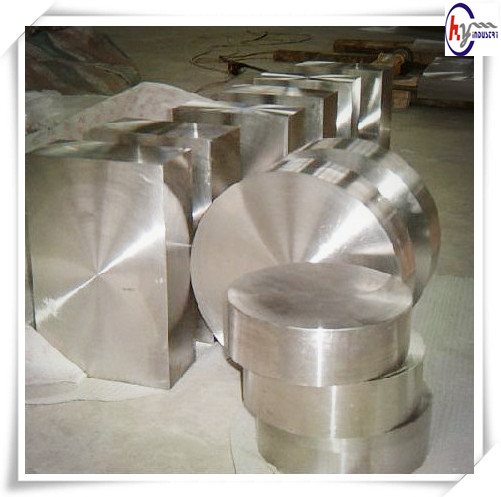

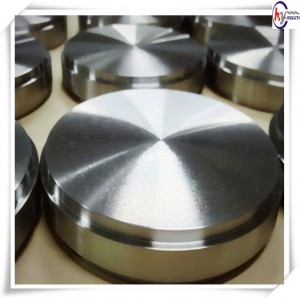

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |