Nickel Alloy Monel 400 UNS N04400

HY M400 Material grades and equivalents

Nonel 400/ Alloy400 /UNS N04400 / SEW VDIUV W.Nr.2.4360 NiCu30Fe /BS NA 12 / AFNOR Nu 30

HY M400 Chemical composition

| Alloy |

% |

Ni |

Cu |

Fe |

C |

Mn |

Si |

S |

|

HY M400 |

Min. |

63 |

28 |

|||||

|

Max. |

34 |

2.5 |

0.3 |

2 |

0.5 |

0.024 |

HY M400 Physical properties

| Density |

8.83 g/cm³ |

|

Melting point |

1300-1390 ℃ |

HY M400 Alloy minimum mechanical properties in the room temperature

| Alloy state |

Tensile strength |

Yield strength |

Elongation |

|

HY M400 |

480 |

170 |

35 |

Characteristic as below:

HY M400 is an extremely combination property that use for largest amount and most widely corrosion resistance alloy. This alloy in the hydrofluoric acid and fluoride gas medium with excellent corrosion resistance, as well as to the hot concentrated alkali. At the same time, is also corrosion resistant to neutral solution, sea water, air, organic compounds. An important feature of this is generally do not generate a stress corrosion cracking, good cutting performance.

HY M400 Metallurgical structure

HY M400 alloy is high-intensity single-phase solid solution.

HY M400 Corrosion resistance

HY M400 alloy in the fluoride gas, hydrochloric acid, sulfuric acid, hydrofluoric acid and their derivatives have a very good corrosion resistance property, and possess better corrosion resistance more than the copper alloy in the sea water. Acid medium: HY M400have corrosion resistance in less than 85% consistency of sulfuric acid. HY M400is an important material that resistant to hydrofluoric acid. Water corrosion: HY M400 alloy in most corrosion cases of water, not only excellent corrosion resistance, but also less pitting, stress corrosion, the corrosion rate less than 0.025mm / a. High temperature corrosion: HY M400 for the work of the highest temperature at about 600 ℃ in general in the air, in the high temperature steam, the corrosion rate less than 0.026mm / a. Ammonia: HY M400 can be resistant to an hydrous ammonia and aminate conditions corrosion below 585 ℃ due to the high nickel.

HY M400 Application field:

HY M400 alloy is a multi-purpose material in many industrial applications:

1. Seamless water pipe in the power factory

2. Sea-water exchanger and evaporator

3. Sulfuric acid and hydrochloric acid environment

4. Crude distillation

5. Sea-water in the use of equipment and propeller shaft

6. Nuclear industry and used in the manufacture of uranium enrichment isotope separation equipment

7. Manufacturing hydrochloric acid equipment used in the production of pump and valve

Specification:

|

Pipe Smls |

Pipe Welded |

Sheet/Plate |

Bar |

Forging |

Fitting |

Wire |

|

B165/ B163 |

B725 |

B127 |

B164 |

B564 |

B366 |

- |

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

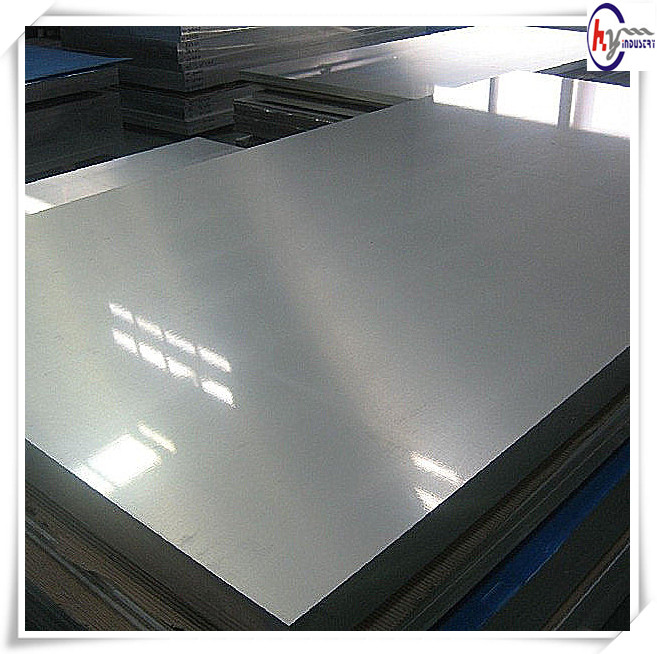

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

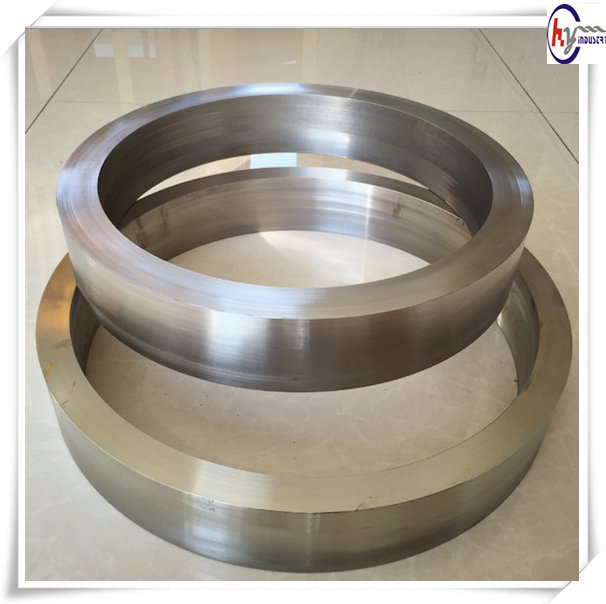

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |