Nickel Alloy Monel K500 UNS N05500

HY MK-500 Material grades and equivalents

Monel K-500/W Nr.2.4375/Nickel-Copper Alloy 500/UNS N05500

HY MK-500 Chemical composition:

| Alloy |

% |

Ni |

Cu |

Al |

Ti |

Fe |

Mn |

S |

C |

Si |

|

Monle K500 |

Min. |

63 |

27.0 |

2.30 |

0.35 |

|||||

|

Max. |

33.0 |

3.15 |

0.85 |

2.0 |

1.5 |

0.01 |

0.25 |

0.5 |

HY MK-500 Physical properties:

|

Density |

8.44 g/cm3 |

|

Melting point |

1315-1350℃ |

HY MK-500 minimum mechanical properties in the room temperature:

| Forms | Condition | Max. section Thickness,in.(mm) | Tensile strength Min. Ksi.(Mpa) | Yield strength Min.Ksi.(Mpa) | Elongation in 2 in,or 4D,min.,% | Hardness | |

| HB min. | HRC min. | ||||||

| Round bars, Hexagons, squares, rectangles and forgings | hot-worked and age hardened | All Sizes | 140(965) | 100(690) | 20 | 265 | 27 |

| Round bars | cold worked and age hardened | 1/4(6.4)to 1(25.4) | 145(1000) | 110(760) | 15 | 300 | 32 |

| over 1(25.4)to 3(76.2) | 140(965) | 100(690) | 17 | 280 | 29 | ||

| over 3(76.2)to 4(101.6) | 135(930) | 99(655) | 20 | 255 | 25 | ||

| Hexagons | cold worked and age hardened | 1/4(6.4)to 2(50.8) | 140(965) | 100(690) | 15 | 265 | 27 |

| Round bars, Hexagons, squares, rectangles and forgings | Annealed and age hardened | Up to 1(25.4) | 130(895) | 90(620) | 20 | 250 | 24 |

| 1(25.4)and over | 130(895) | 85(585) | 20 | 250 | 24 | ||

HY MK-500 has approximately twice the tensile strength and triple the yield strength of Alloy 400. The strength of Alloy K-500 is maintained to 1200 degrees Fahrenheit, but stays ductile and tough down to temperatures of -400 degrees Fahrenheit. Alloy K-500 also stays non-magnetic to -200 degrees Fahrenheit.

Additional characteristics of Alloy K-500 include outstanding corrosion resistance in a wide range of chemical and marine surroundings, from salts and alkalis, non-oxidizing acids to pure water. HY MK-500 is non-magnetic and spark resistant. It is also recommended that Alloy K-500 be annealed when it is welded and that any weldments be stress relieved prior to aging.

Industries Served:

gas & oil extraction

chemical processing

marine engineering

Specification:

|

bar/rod |

AMS 4676 |

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

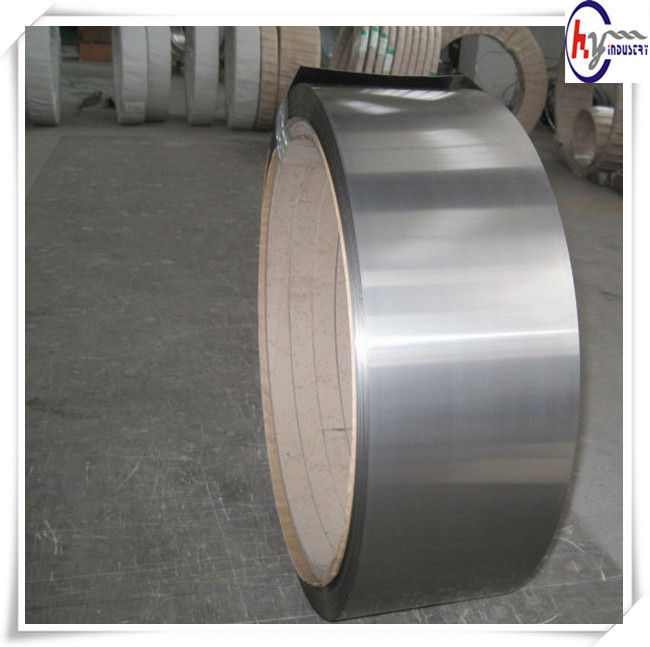

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

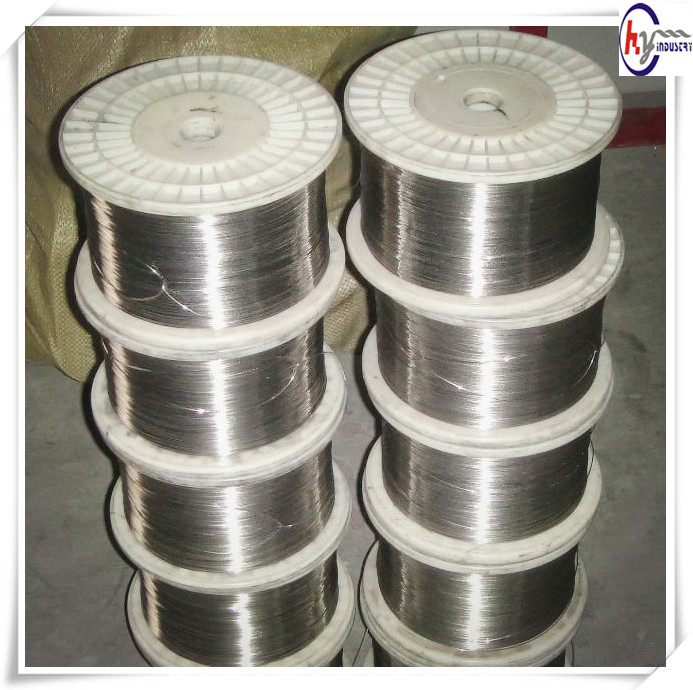

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

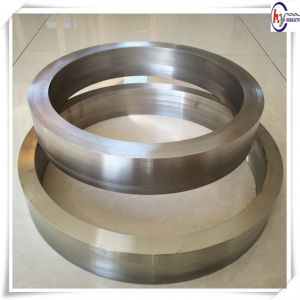

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |