Nickel Alloy Nimonic 75 UNS N06075

HY N75 Material grades and equivalents

Nimonic 75/ UNS N06075 / W.Nr. 2.4951 / W.Nr. 2.4630 / AFNOR NC20T

Chemical Composition:

|

Alloy |

% |

C |

Cr |

Ni |

Ti |

Fe |

Cu |

Mn |

Si |

|

75 |

Min. |

0.08 |

18 |

Balance |

0.2 |

||||

|

Max |

0.15 |

21 |

0.6 |

5 |

0.5 |

1 |

1 |

HY N75 Physical properties:

|

Density |

8.37 g/cm3 |

|

Melting point |

2450-2520℃ |

HY N75 minimum mechanical properties in the room temperature:

|

Alloy |

Tensile strength |

Thermal conductivity |

Coefficient of thermal expansion |

HardnessHB |

|

Rm N/mm2 |

W/m• °C |

μm/m/°C |

||

|

HY N75(solution) |

1400-2210 |

11.7 |

11 |

241 |

Alloy 75 (UNS N06075) is a nickel-chromium alloy with good mechanical properties and oxidation resistance at high temperatures. Alloy 75 is most commonly used for sheet metal fabrications which require oxidation and scaling resistance together with medium strength at high operating temperatures. Alloy 75 is also used in gas turbine engines, for components of industrial furnaces, for heat treating equipment and fixtures, and in nuclear engineering.

Specifications

| Rod, Bar, Wire and Forging Stock | BS HR 5, BS HR 504, DIN 17752, AECMA PrEN2306, AECMA PrEN2307, AECMA PrEN2306, AECMA Pr EN2307, AECMA PrEN2402, ISO 9723, ISO 9724, ISO 9725 |

| Plate, Sheet, Strip | BS HR 203, DIN 17750, AECMA PrEN2293, AECMA PrEN2302, AECMA PrEN2411, ISO 6208 |

| Pipe and Tube | BS HR 403, DIN 17751, AECMA PrEN2294, ISO 6207 |

| Other | DIN 17742, AECMA PrEN2308, Werkstoff Nr 2.4630, W. Nr 2.4951, UNS N06075, HY N75 (tradename), MSRR 7104 and MSRR 7004, AFNOR NC 20T |

Typical Mechanical Properties Alloy 75

| Rupture Strength (1000 h) | ||

|

Temperature |

psi |

MPa |

|

760°C / 1400° F |

6000 |

40 |

|

815°C / 1500°F |

3500 |

24 |

|

870°C / 1600°F |

2200 |

15 |

|

925°C / 1700°F |

1500 |

10 |

|

980°C / 1800°F |

1200 |

8 |

Specification:

|

Rod, Bar, Wire and Forging Stock |

BS HR 5, BS HR 504, DIN 17752, AECMA PrEN2306, AECMA PrEN2307, AECMA PrEN2306, AECMA Pr EN2307, AECMA PrEN2402, ISO 9723, ISO 9724, ISO 9725, MSRR 7004 |

|

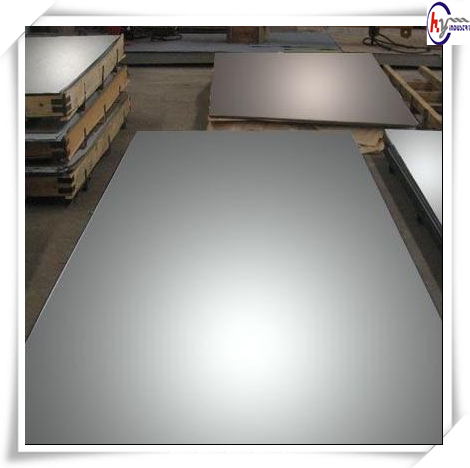

Plate, Sheet, Strip |

BS HR 203, DIN 17750, AECMA PrEN2293, AECMA PrEN2302, AECMA PrEN2411, ISO 6208, MSRR 7104 |

|

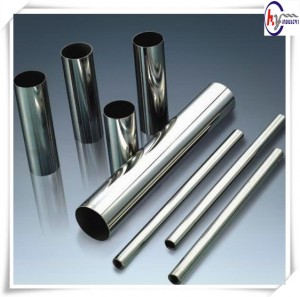

Pipe and Tube |

BS HR 403, DIN 17751, AECMA PrEN2294, ISO 6207 |

(This material was Annealed)

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

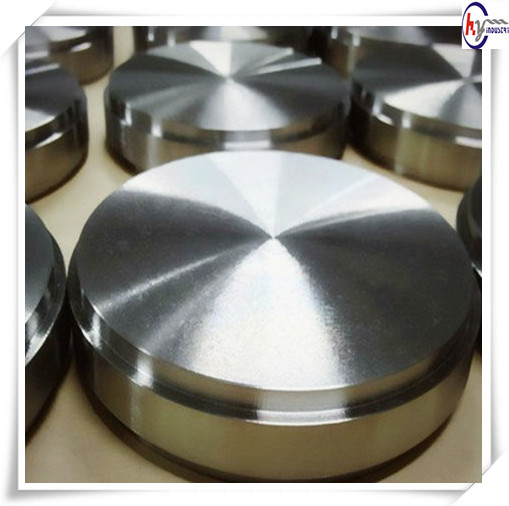

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |