11 Years Manufacturer Nickel Alloy Incoloy 800 UNS N08800 to moldova Factory

As for competitive prices, we believe that you will be searching far and wide for anything that can beat us. We can state with absolute certainty that for such quality at such prices we are the lowest around for 11 Years Manufacturer Nickel Alloy Incoloy 800 UNS N08800 to moldova Factory, We are confident to make great achievements in the future. We are looking forward to becoming one of your most reliable suppliers.

HY 800

Material grades and equivalents

Incoloy 800/GB NS111/UNS N08800/SEW VDIUV W.Nr.1.4876 X10NiCrAlTi3220/BS NA15/AFNOR Z8NC32.21

HY 800 Chemical composition:

|

Alloy |

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

Cu |

S |

Al |

Ti |

|

800 |

Min. |

30 |

19 |

0.15 |

0.15 |

||||||

|

Max. |

35 |

23 |

balance |

0.1 |

1.5 |

1 |

0.75 |

0.015 |

0.6 |

0.6 |

|

|

800H |

Min. |

30 |

19 |

0.05 |

0.15 |

0.15 |

|||||

|

Max. |

35 |

23 |

balance |

0.1 |

1.5 |

1 |

0.75 |

0.015 |

0.6 |

0.6 |

|

|

800HT |

Min. |

30 |

19 |

0.06 |

0.15 |

0.15 |

|||||

|

Max. |

35 |

23 |

balance |

0.1 |

1.5 |

1 |

0.75 |

0.015 |

0.6 |

0.6 |

|

|

AI+Ti: 0.85-1.20 |

|||||||||||

HY 800 Physical properties

|

Density |

8.0 g/cm³ |

|

Melting point |

1350-1400 °C |

HY 800 Alloy minimum mechanical properties in the room temperature

|

Alloy |

Tensile strength |

Yield strength |

Elongation |

|

Rm N/mm² |

R P 0. 2N/mm² |

A 5 % |

|

|

800 |

500 |

210 |

35 |

|

800H |

450 |

180 |

35 |

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

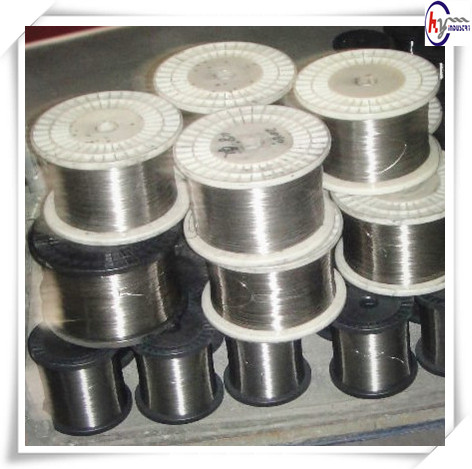

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

.025″ slash, 140sfm, VBMT 331 insert

I am earning my own wedding day band from Inconel X-750 just to be diverse. The material is a agony to do the job with thanks to the superior nickel/chromium articles. The lathe is a LeBlond “dual generate” with an Aloris-copy device article. I built an adapter for the one.25″ boring bar socket to sleeve it down to a 5/8″ side-lock drill shank. I utilised an indicator to sweep the device holder, inserting it instantly on center. The drill is a Seco CrownLoc As well as with .625″ tip, running at around 80sfm, hand feed with plenty of stress, and drenched in reducing oil (not demonstrated in pic). Chips had been astonishingly limited of course, I had to withdrawal the device numerous moments to eliminate chips, due to the fact they weren’t becoming flushed by coolant.