2 Years’ Warranty for Iron Alloy Precision Alloy 1J50 Factory for Istanbul

We have a highly efficient team to deal with inquiries from customers. Our goal is "100% customer satisfaction by our product quality, price & our team service" and enjoy a good reputation among clients. With many factories, we can provide a wide range of 2 Years’ Warranty for Iron Alloy Precision Alloy 1J50 Factory for Istanbul, We sincerely welcome domestic and foreign merchants who calls, letters asking, or to plants to negotiate, we will offer you quality products and the most enthusiastic service,We look forward to your visit and your cooperation.

HY J50 Material grades and equivalents

1J50 / JIS PB

HY J50 Chemical composition

|

Grade |

C |

P |

S |

Mn |

Ni |

Si |

Mn |

Cu |

Fe |

||||

|

≤ |

|||||||||||||

| HY J50 |

0.03 |

0.020 |

0.020 |

0.3-0.6 |

49.5-50.5 |

0.15-0.30 |

0.30-0.60 |

≤0.20 |

Rest |

||||

HY J50 Alloy Mechanical properties in the room temperature

|

Grade |

Shape |

Magnetic properties |

|||

|

Initial permeabilityμO |

Maximum permeabilityμm |

Hc |

Saturation induction density BS |

||

|

HY J50 |

Cold rolling strips |

≥3.8 |

≥62.5 |

≤9.6 |

1.5 |

|

Forging bar |

≥3.1 |

≥31.3 |

≤14.4 |

1.5 |

|

HY J50 Characteristic as below

The HY J50 has rectangular hysteresis loop and high saturation magnetic induction, is mainly used to worked at a moderate magnetic field magnetic amplifier, choke ring, rectifier circle, as well as the computer device components.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

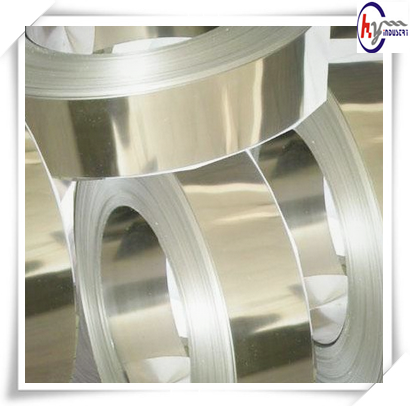

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

I am earning my own wedding day band from Inconel X-750 just to be diverse. The material is a agony to do the job with thanks to the superior nickel/chromium articles. The lathe is a LeBlond “dual generate” with an Aloris-copy device article. I built an adapter for the one.25″ boring bar socket to sleeve it down to a 5/8″ side-lock drill shank. I utilised an indicator to sweep the device holder, inserting it instantly on center. The drill is a Seco CrownLoc As well as with .625″ tip, running at around 80sfm, hand feed with plenty of stress, and drenched in reducing oil (not demonstrated in pic). Chips had been astonishingly limited of course, I had to withdrawal the device numerous moments to eliminate chips, due to the fact they weren’t becoming flushed by coolant.

.025″ slash, 140sfm, VBMT 331 insert