20 Years manufacturer Iron Alloy Precision Alloy UNS N08031 Alloy 31 to Curacao Manufacturer

Innovation, quality and reliability are the core values of our company. These principles today more than ever form the basis of our success as an internationally active mid-size company for 20 Years manufacturer Iron Alloy Precision Alloy UNS N08031 Alloy 31 to Curacao Manufacturer, Please send us your specifications and requirements, or feel free to contact us with any questions or inquiries that you may have.

HY A31 Material grades and equivalents

AISI/ASTM Alloy 31 / UNS N08031 / W.Nr 1.4562

Chemical composition:

| Alloy | % | Ni | Cr | Fe | Mo | N | C | Mn | Si | 硫 | 铜 | 磷 |

| HY A31 | Min | 30 | 26 | 余量 | 6 | 0.15 | 1 | |||||

| Max | 32 | 28 | 7 | 0.25 | 0.015 | 2 | 0.3 | 0.01 | 1.4 | 0.02 | ||

| Physical properties: | ||||||||||||

| Density | 8.1 g/cm3 | |||||||||||

| Melting point | 1350-1370 ℃ | |||||||||||

| Alloy minimum mechanical properties in the room temperature: | ||||||||||||

| Alloy | Tensile strength Rm N/mm² | Yield strength Rp0.2 N/mm² | Elongation A5 % | |||||||||

| Solution | 650 | 350 | 35 | |||||||||

Characteristic as below:

HY A31 is a nitrogen-containing iron-nickel-molybdenum alloy performance between super austenitic stainless steel and nickel-based alloy, suitable for used in chemical and petrochemical, environment engineering, oil and gas production industrial fields.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

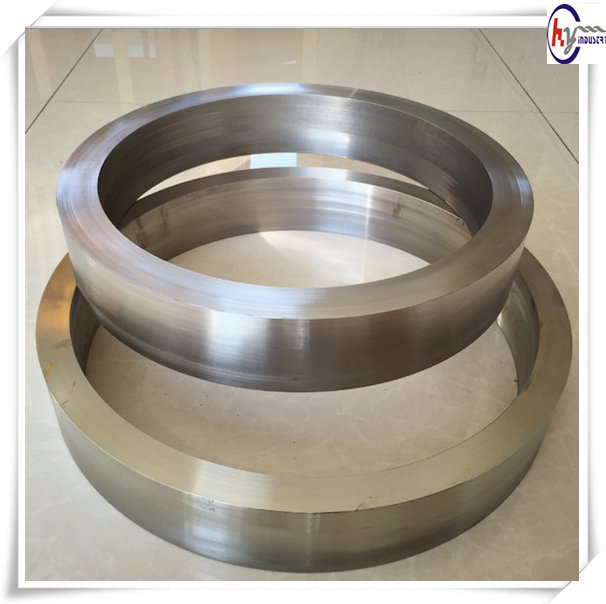

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

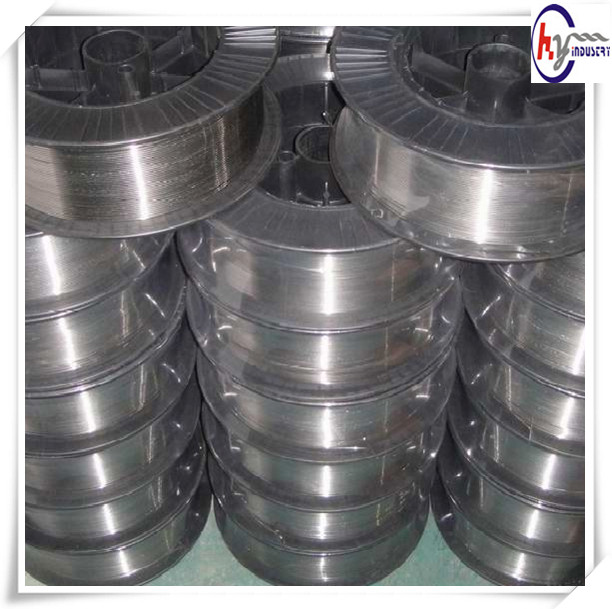

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Welding Inconel 718

Supplier foil、strip、sheet、coil、plate、wire、rod、bar、tube、pipe、flat ribbon、Profiled wire…

BuildingNo.1,Third Industrial District XiTou Village SongGang City Bao’An District ShenZhen Metropolis GuangDong Province China