80% OFF Price For Cobalt Alloy Stellite 6 UNS R3006 to San Diego Factory

With a positive and progressive attitude to customer's interest, our company continuously improves our product quality to meet the needs of customers and further focuses on safety, reliability, environmental requirements, and innovation of

80% OFF Price For Cobalt Alloy Stellite 6 UNS R3006 to San Diego Factory, "Passion, Honesty, Sound service, Keen cooperation and Development" are our goals. We are here expecting friends all over the world!

HY S6 Material grades and equivalents: Stellit 6; UNS R3006; AMS 5387C-2001

Introduction:

HY S6 is the most widely used of the wear resistant cobalt-based alloys and exhibits good all-round performance. It is regarded as the industry standard for general-purpose wear resistance applications.

HY S6 Chemical components

|

C |

Cr |

Si |

W |

Fe |

Mo |

Ni |

Mn |

B |

Co |

|

1.2 |

28 |

1.1 |

4.5 |

3 |

3 |

1 |

bal |

||

| *The chemical composition shown above is an outline only,and should not be taken as a full specification. *Note that cored wire may have higher Fe contents than other product forms. |

|||||||||

HY S6 Physical property (Room Temp.)

| Density (lb/in³) |

Specific Gravity |

Solidus | Liquidus | Specific heat (J/kg·K) |

Magnetic Permeability |

Electrode Potential |

Electrical Conductivity |

Electrical Resistivity |

| 0.305 | 8.46 | 2340°F | 2540°F | 0.101°F Btu/lb- |

<1.2@200 Oersteds |

-0.25 Volts |

1.9%IACS (Int. Annealed Copper Std.) |

41.73 microhms-inch |

HY S6 Thermal Properties-Conductivity & Expansion

| Thermal Expansion Coefficient | Thermal Conductivity by Temperature | ||||||

| °F | Microinch/ inch-°F |

°C | Microns/ m-°C |

°F | Btu/ft2/in/ hr/°F |

°C | W/mk |

| 212 | 6.3 | 100 | 11.34 | 70 | 102.7 | 21.11 | 14.82 |

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

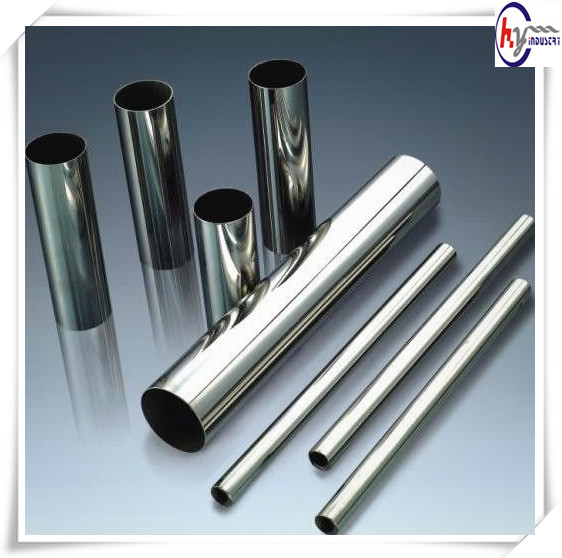

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

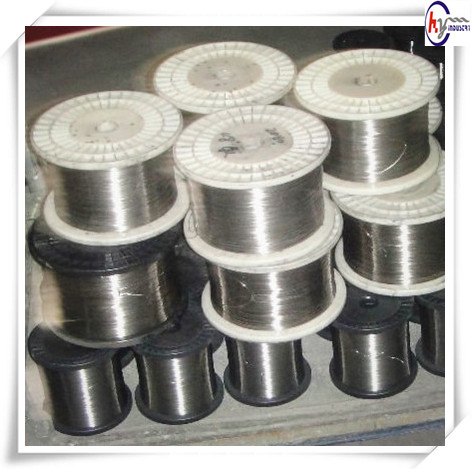

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

NEW 2016 Chrysler three hundred S Alloy Edition Sedan with a Gloss Black Paint finish. AWD that seats five with a three.two L V-six engine and an eight velocity computerized transmission. 19″ alluminum alloy rims with Michelin Primacy MXM4 tires. This sedan will come thoroughly loaded with keyless entry, distant get started, power locks, home windows, mirrors, Beats by Dre audio system, AM/FM, Sirius Sat radio, Lcd display screen in the entrance with back up digicam, leather all over with heated entrance and rear seats and so significantly a lot more. Come check out it out at Ponoka Chrysler and see what else it has to present, we are located on the south conclusion of Ponoka just off of HWY 2A.

Stock# 16C37644

Sarah Johnson,

Ponoka Chrysler

6510 39th Ave Ponoka, AB T4J 1J8

Toll Cost-free: 1(800) 265-6851

Cellphone: (403) 783-5383

Fax: (403) 783-8140

E-mail: sjohnson@ponokachrysler.com

Like us on Fb- https://www.facebook.com/PonokaChrysler/

Abide by us on Instargram- https://www.instagram.com/ponokadodge/

Abide by us on Twitter- https://twitter.com/PonokaDodgeRam

Abide by us on Pintrest- https://www.pinterest.com/ponokachrysler/

The progress of improved metallic resources is a crucial action at the leading edge of science and know-how. Metals offer unrivalled mixtures of houses and reliability at a cost which is economical. They are adaptable mainly because subtle improvements in their microstructure can cause dramatic variations in their houses. For illustration, it is feasible to purchase business steel with a energy as lower as 50 MPa or as large as 5500 MPa. They can be built with a microstructure which is finer than that of carbon nanotubes. An understanding of the progress of microstructure in metals, rooted in thermodynamics, crystallography and kinetic phenomena is crucial for the resources scientist. The bulk of the 1.4 billion tonnes of metals made annually are the outcome of developments within just the last 10 a long time

http://www.msm.cam.ac.british isles/phase-trans/2002/creep.1.html