Big discounting Nickel Alloy Inconel X-750 UNS N07750 for Bulgaria Manufacturers

We stick to our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We aim to create more value for our customers with our rich resources, advanced machinery, experienced workers and excellent services for Big discounting Nickel Alloy Inconel X-750 UNS N07750 for Bulgaria Manufacturers, We sincerely welcome both foreign and domestic business partners, and hope to work with you in the near future!

HY X-750 Material grades and equivalents

Inconel X-750 / GB GH4145 / UNS N07750/W.Nr.2.4669 NiCr15Fe7TiAl / AFNOR NC15FeT

HY X-750 Chemical composition:

|

Alloy |

% |

Ni |

Cr |

Fe |

Nb |

Co |

C |

Mn |

Si |

S |

Cu |

Al |

Ti |

|

HY X-750 |

Min. |

14 |

5 |

0.7 |

0.4 |

2.25 |

|||||||

|

Max. |

70 |

17 |

9 |

1.2 |

1 |

0.08 |

1 |

0.5 |

0.01 |

0.5 |

1 |

2.75 |

HY X-750 Physical properties:

|

Density |

8.28 g/cm3 |

|

Melting range |

1393-1427℃ |

HY X-750 Alloy m inimum Mechanical properties in the room temperature:

|

Alloy |

Tensile strength |

Yield strength RP0.2N/mm2 |

ElongationA5 % |

Brinell hardness HB |

|

Solution treatment |

1267 |

868 |

25 |

≤400 |

HY X-750 Characteristic as below::

HY X-750 is a precipitation-hardenable alloy which has been used in applications such as high temperature structural members for gas turbines, jet engine parts, nuclear power plant applications, heat-treating fixtures, forming tools, and extrusion dies. The alloy is highly resistant to chemical corrosion and oxidation and has high stress-rupture strength and low creep rates under high stresses at temperatures up to 1500°F (816°C) after suitable heat treatment.

HY X-750 Machinability:

Conventional machining techniques used for iron based alloys may be used. This alloy does work-harden during machining and has higher strength and “gumminess” not typical of steels. Heavy duty machining equipment and tooling should be used to minimize chatter or work-hardening of the alloy ahead of the cutting.

HY X-750 Corrosion resistance:

HY X-750 has excellent resistance to chloride ion stress-corrosion cracking. It exhibits satisfactory resistance to numerous oxidizing environments. The alloy has similar corrosion resistance to alloy 600 in many media.

HY X-750 Application range and field:

- Nuclear reactors

- Gas turbines

- Rocket engines

- Pressure vessels

Aircraft structures

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

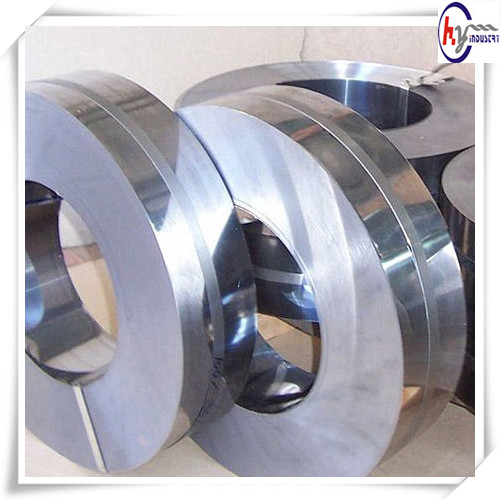

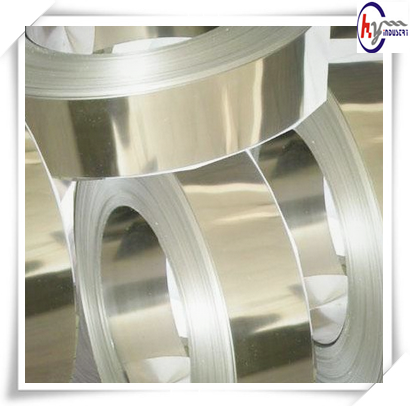

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Visit my site for additional Recommendations, Films, Do it yourself assignments and additional:

http://www.mjlorton.com/

—————————–Click “Display additional”—————————————

A information on making use of the correct applications to crimp connectors, strip wire and implement warmth shrink.

You should guidance my information generation by making use of my Amazon Retail store:

http://astore.amazon.com/m0711-twenty

Purchase these applications and connectors below: http://astore.amazon.com/m0711-twenty?node=ten&site=one

——————— Click “Display additional” ——————————-

My site and forum:- http://www.mjlorton.com

Donations and contributions:- http://www.mjlorton.com

My techie channel MJLorton – Solar Power and Digital Measurement Products – http://www.youtube.com/MJLorton

My Techie Amazon Retail store: http://astore.amazon.com/m0711-twenty

My other channel VBlogMag – For nearly any matter beneath the sun! – http://www.youtube.com/VBlogMag

My VBlogMag Amazon Retail store: http://astore.amazon.com/vblogmag-twenty

———————————————————————–

=================================================

Online video sponsor, Pass Ltd – their internet websites:

http://www.tester.co.united kingdom/?cmid=QmhzQjcxYjVlc1E9&afid=bFcwbzliNzVDc289&ats=K2EyUjZNTDh3UTA9 – Examination Products and Examination-meter suppliers and

http://www.calibrate.co.united kingdom/?cmid=QmhzQjcxYjVlc1E9&afid=bFcwbzliNzVDc289&ats=S3Yxd2tOMjVISzA9 – Calibration and support of exam tools

=================================================

Additional dialogue and link to NASA information below:

http://mjlorton.com/forum/index.php?matter=244.

In this online video:

* Deciding upon the correct wire gauge (AWG – American Wire Gauge) for the crimp connector.

* Employing the correct applications to strip the insulation from the wire.

* The correct way to insert the wire into the crimp connector

* Employing the correct crimp applications to crimp the connector

* How to implement warmth shrink accurately to the wire and crimp connector.

To comprehend that the utilizes for particular metals relate to their unique qualities.

To comprehend that the qualities of metals can be improved by generating alloys.

To recall that some of the hottest alloys, called ‘Smart Alloys’ can change their qualities on demand from customers.

Duplicate the table beneath. Working with a companion, entire as a great deal of the table as you can.

Very low density, powerful, resistant to corrosion, very good conductor of energy

Good conductor of energy, resistant to corrosion, quickly formed, flexible

Shiny, very resistant to corrosion, very unreactive, soft, quickly formed

Extremely powerful, very dense.

Lightweight buildings, plane, drinks cans, higher voltage cables.

Electrical wiring, h2o pipes.

Jewelry.

Substantial buildings and significant responsibility engineering these as bridges, trains, autos and so forth.

In pure metals the atoms prepare them selves closely collectively into regular styles. This tends to make them dense and also presents them numerous of their other helpful qualities.

The layer arrangement of the atoms permits the metals to transform form if a pressure is utilized. The layers can slip around every other.

This can be helpful if you want to form the steel but not so helpful if you want it to resist the pressure and be powerful.

By mixing two or additional metals collectively the regular arrangement of the atoms is disrupted. This stops the atoms forming layers and tends to make it harder for the atoms to slide around every other. The alloy is more robust than the pure metals.

Steel B

Steel A

Steel is an alloy. Pure iron is not powerful enough to be employed in buildings. Steel contains a smaller amount of carbon. This disrupts the layers of atoms in the steel and improves the toughness of the steel considerably.

Despite the fact that it is very powerful metal will corrode (rust) quickly and it has to be regularly protected from the consequences of h2o and air.

Stainless metal is an alloy that contains other metals these as Nickel and Chromium. Stainless metal has the toughness of metal mixed with the corrosion resistance of nickel and the shininess of chromium. This tends to make it a helpful materials in programs exactly where you will need toughness mixed with magnificence and corrosion resistance..

Clever Alloys

These are alloys that can ‘remember’ their primary form. If they are deformed they can return to their primary form.

Condition memory glasses

Condition memory Stent to continue to keep a blocked blood vessel open

Metals, Alloys and Clever Alloys

Finding out Objectives:

To comprehend that the utilizes for particular metals relate to their unique qualities.

To comprehend that the qualities of metals can be improved by generating alloys.

To recall that some of the hottest alloys, called ‘Smart Alloys’ can change their qualities on demand from customers.