Cheapest Price Nickel Alloy Hastelloy X UNS N06002 in Hawaii

We are proud of the high customer satisfaction and wide acceptance due to our persistent pursuit of high quality both on product and service for Cheapest Price Nickel Alloy Hastelloy X UNS N06002 in Hawaii, We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

HY HX Material grades and equivalents

Hastelloy X / GB GH3536&GH536/UNS N06002 / SEW VDIUV W.Nr.2.4613 / AFNOR NC22FeD

| HY HX | ||||||||||||||||

| UNS | Trademark | W.Nr | ||||||||||||||

| N06002 | HY HX | 2.4613 | ||||||||||||||

| HY HX Chemical compostion: | ||||||||||||||||

| Alloy | % | Ni | Cr | Fe | C | Mn | Si | Cu | S | B | Ti | P | Co | W | Mo | Al |

| HY HX | Min. | balance | 20.5 | 17 | 0.05 | 0.5 | 0.2 | 8 | ||||||||

| Max. | 23 | 20 | 0.15 | 1 | 1 | 0.5 | 0.015 | 0.01 | 0.15 | 0.025 | 2.5 | 1 | 10 | 0.5 | ||

| HY HX Physical properties: | ||||||||||||||||

| Density | 8.28 g/cm3 | |||||||||||||||

| Melting Point | 1295-1381 ℃ | |||||||||||||||

Hastelloy X Characteristic:

Good oxidation and corrosion resistance. Below 900 °C with middle elevated temperature stress rupture and creep rupture strength; good formability with cold working and hot working and excellent welding fabrication.

Hastelloy X Applied field:

Aero-engine combustion chamber and other parts used at elevated temperatures,long term usage below 900°C,short term usage temperature can reach 1080°C.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

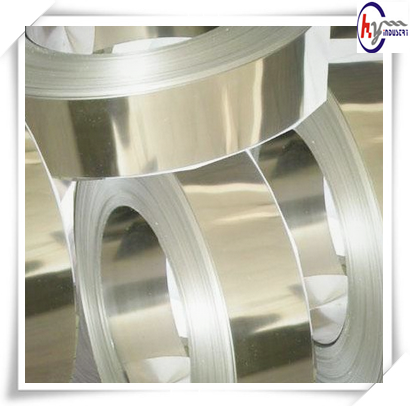

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Qingdao NPA Marketplace Co. Ltd is a foremost manufacturer specialized in centrifugal casting tube and static castings of warmth resistant alloys, which include ethylene cracking furnace tube, reformer furnace tube, CAL(constant annealing traces) &CGL(constant galvanizing traces) furnace roller and radiant tube, glass lehr roller and warmth/have on resistant castings. The annual potential is 9000 tons centrifugal casting tube and 3500 tons static castings (500 tons precision castings).

Internet site: www.npa-china.com

Provider foil、strip、sheet、coil、plate、wire、rod、bar、tube、pipe、flat ribbon、Profiled wire…

BuildingNo.one,3rd Industrial District XiTou Village SongGang City Bao’An District ShenZhen Town GuangDong Province China