China Professional Supplier Iron Alloy Precision Alloy 1J79 Alloy4 Factory in Greece

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for China Professional Supplier Iron Alloy Precision Alloy 1J79 Alloy4 Factory in Greece, We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

HY J79 Material grades and equivalents

1J79 / AISI/ASTM Alloy4

HY J79 Chemical composition

|

Grade |

C |

P |

S |

Mn |

Ni |

Si |

Mo |

Cu |

Fe |

||||

|

≤ |

|||||||||||||

| HY J79 |

0.03 |

0.02 |

0.02 |

0.6-1.1 |

78.5-80.5 |

0.3-0.5 |

3.8-4.1 |

≤0.20 |

Rest |

||||

HY J79 Alloy Mechanical properties in the room temperature

|

Grade |

Shape |

Magnetic properties |

|||

|

Initial permeabilityμO |

Maximum permeabilityμm |

Hc |

Saturation induction density BS |

||

|

HY J79 |

Cold rolling strips |

≥31 |

≥250 |

≤1.2 |

0.75 |

|

Rod wire |

≥25 |

≥3125 |

≤2.4 |

0.75 |

|

HY J79 Characteristic as below

HY J79 has a high initial permeability, to work in a weak magnetic field of various transformers, transformers, magnetic amplifiers, choke coil core and magnetic shielding.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

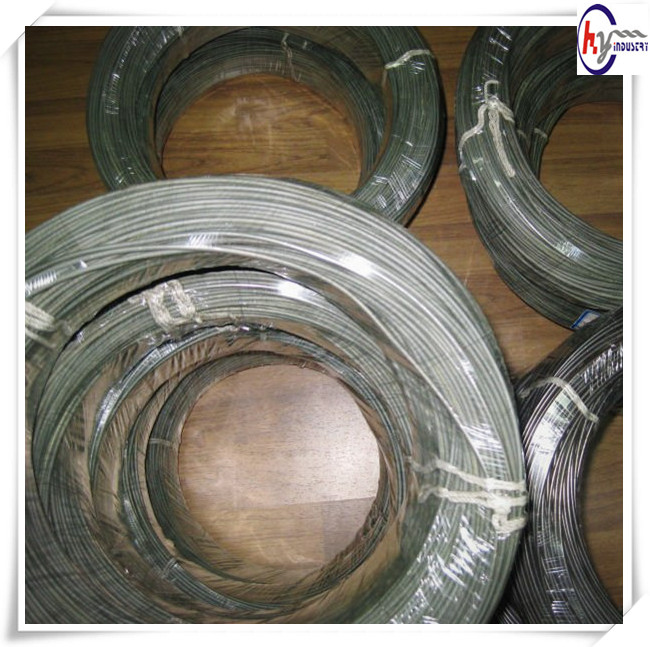

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Welding Inconel 718

Riporto(placcatura)con filo Nimonic 80 dia. one.2 eseguito con inverter multiprocesso Weldtronic Synertech 8004 Digit in pulsato sinergico.

NB .Il lampeggio dell’arco è presente solo nella ripresa effettuata dalla fotocamera digitale usata probabilmente a causa di interferenza con l’intenso arco luminoso.

Details: belda1@tiscali.it