Goods high definition for Nickel Alloy Incoloy 800 UNS N08800 Wholesale to Slovakia

Innovation, quality and reliability are the core values of our company. These principles today more than ever form the basis of our success as an internationally active mid-size company for Goods high definition for Nickel Alloy Incoloy 800 UNS N08800 Wholesale to Slovakia, we are looking forward to even greater cooperation with overseas customers based on mutual benefits. Please feel free to contact us for more detail

HY 800

Material grades and equivalents

Incoloy 800/GB NS111/UNS N08800/SEW VDIUV W.Nr.1.4876 X10NiCrAlTi3220/BS NA15/AFNOR Z8NC32.21

HY 800 Chemical composition:

|

Alloy |

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

Cu |

S |

Al |

Ti |

|

800 |

Min. |

30 |

19 |

0.15 |

0.15 |

||||||

|

Max. |

35 |

23 |

balance |

0.1 |

1.5 |

1 |

0.75 |

0.015 |

0.6 |

0.6 |

|

|

800H |

Min. |

30 |

19 |

0.05 |

0.15 |

0.15 |

|||||

|

Max. |

35 |

23 |

balance |

0.1 |

1.5 |

1 |

0.75 |

0.015 |

0.6 |

0.6 |

|

|

800HT |

Min. |

30 |

19 |

0.06 |

0.15 |

0.15 |

|||||

|

Max. |

35 |

23 |

balance |

0.1 |

1.5 |

1 |

0.75 |

0.015 |

0.6 |

0.6 |

|

|

AI+Ti: 0.85-1.20 |

|||||||||||

HY 800 Physical properties

|

Density |

8.0 g/cm3 |

|

Melting point |

1350-1400 °C |

HY 800 Alloy minimum mechanical properties in the room temperature

|

Alloy |

Tensile strength |

Yield strength |

Elongation |

|

Rm N/mm2 |

R P 0. 2N/mm2 |

A 5 % |

|

|

800 |

500 |

210 |

35 |

|

800H |

450 |

180 |

35 |

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

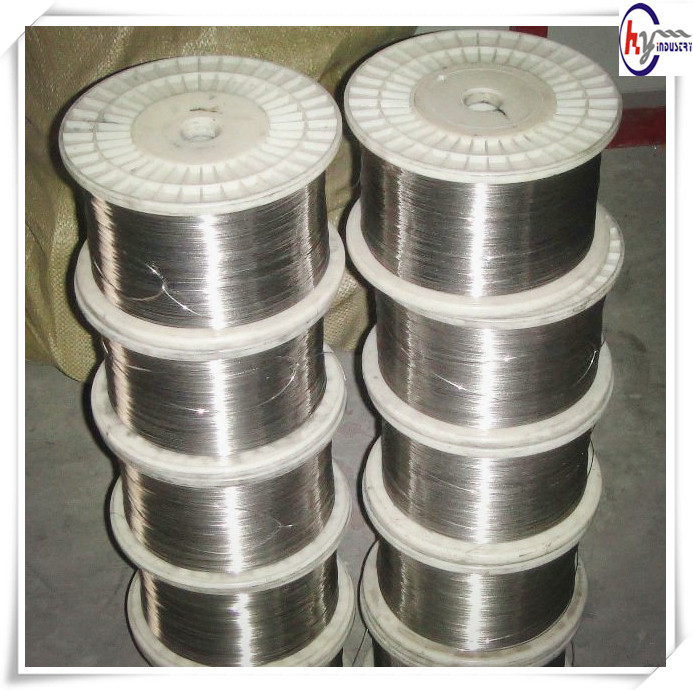

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

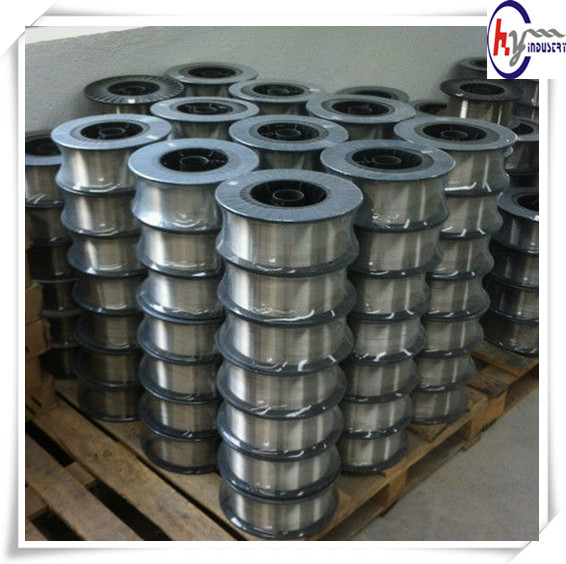

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

http://www.GovLiquidation.com – This 69,560 lbs of Inconel 625 scrap steel has been bought. To look at a current checklist of obtainable scrap steel material, pay a visit to http://bit.ly/jL05Ke currently!

This Inconel was in matrix roll kind and free in pans. This good deal of significant temp alloy scrap steel consisted of Carbon: max .10%, Chromium: min 20% max 23%, Iron: max 5%, Silicon: max .fifty%, Manganese: max .fifty%, Sulfur: max .015%, Phosphorus: max .015%, Molybdenum: min 8% max 10%, Titanium: max .forty%, Nickel: Stability.

This material was positioned in Anniston, AL.

To look at a current checklist of obtainable scrap steel material, pay a visit to http://bit.ly/jL05Ke currently!

.025″ slash, 140sfm, VBMT 331 insert