Reliable Supplier Iron Alloy Precision Alloy 1J50 to United States Factories

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for Reliable Supplier Iron Alloy Precision Alloy 1J50 to United States Factories, Adhering to the business principle of mutual benefits, we have won good reputation among our customers because of our perfect services, quality products and competitive prices. We warmly welcome customers from home and abroad to cooperate with us for common success.

HY J50 Material grades and equivalents

1J50 / JIS PB

HY J50 Chemical composition

|

Grade |

C |

P |

S |

Mn |

Ni |

Si |

Mn |

Cu |

Fe |

||||

|

≤ |

|||||||||||||

| HY J50 |

0.03 |

0.020 |

0.020 |

0.3-0.6 |

49.5-50.5 |

0.15-0.30 |

0.30-0.60 |

≤0.20 |

Rest |

||||

HY J50 Alloy Mechanical properties in the room temperature

|

Grade |

Shape |

Magnetic properties |

|||

|

Initial permeabilityμO |

Maximum permeabilityμm |

Hc |

Saturation induction density BS |

||

|

HY J50 |

Cold rolling strips |

≥3.8 |

≥62.5 |

≤9.6 |

1.5 |

|

Forging bar |

≥3.1 |

≥31.3 |

≤14.4 |

1.5 |

|

HY J50 Characteristic as below

The HY J50 has rectangular hysteresis loop and high saturation magnetic induction, is mainly used to worked at a moderate magnetic field magnetic amplifier, choke ring, rectifier circle, as well as the computer device components.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

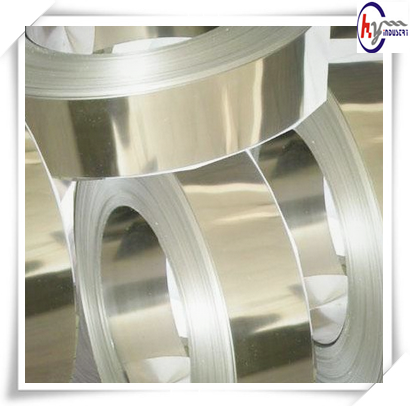

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

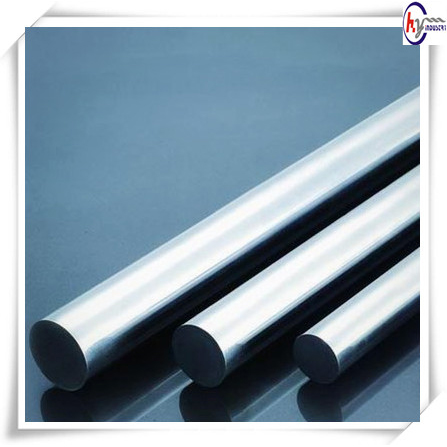

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

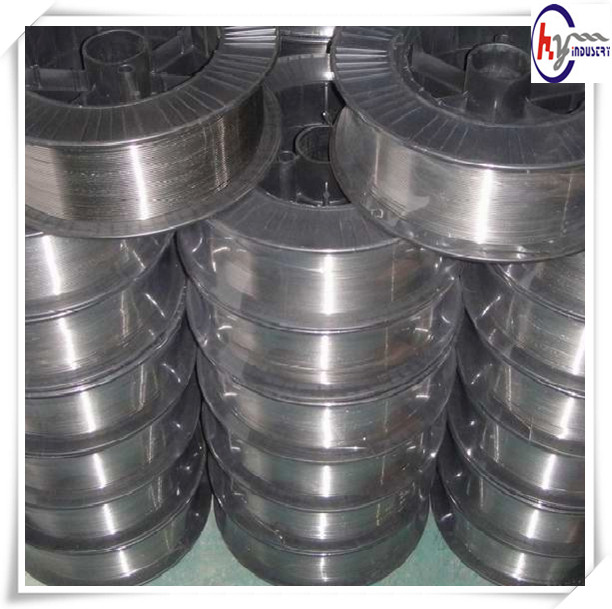

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Visit my site for additional Recommendations, Films, Do it yourself assignments and additional:

http://www.mjlorton.com/

—————————–Click “Display additional”—————————————

A information on making use of the correct applications to crimp connectors, strip wire and implement warmth shrink.

You should guidance my information generation by making use of my Amazon Retail store:

http://astore.amazon.com/m0711-twenty

Purchase these applications and connectors below: http://astore.amazon.com/m0711-twenty?node=ten&site=one

——————— Click “Display additional” ——————————-

My site and forum:- http://www.mjlorton.com

Donations and contributions:- http://www.mjlorton.com

My techie channel MJLorton – Solar Power and Digital Measurement Products – http://www.youtube.com/MJLorton

My Techie Amazon Retail store: http://astore.amazon.com/m0711-twenty

My other channel VBlogMag – For nearly any matter beneath the sun! – http://www.youtube.com/VBlogMag

My VBlogMag Amazon Retail store: http://astore.amazon.com/vblogmag-twenty

———————————————————————–

=================================================

Online video sponsor, Pass Ltd – their internet websites:

http://www.tester.co.united kingdom/?cmid=QmhzQjcxYjVlc1E9&afid=bFcwbzliNzVDc289&ats=K2EyUjZNTDh3UTA9 – Examination Products and Examination-meter suppliers and

http://www.calibrate.co.united kingdom/?cmid=QmhzQjcxYjVlc1E9&afid=bFcwbzliNzVDc289&ats=S3Yxd2tOMjVISzA9 – Calibration and support of exam tools

=================================================

Additional dialogue and link to NASA information below:

http://mjlorton.com/forum/index.php?matter=244.

In this online video:

* Deciding upon the correct wire gauge (AWG – American Wire Gauge) for the crimp connector.

* Employing the correct applications to strip the insulation from the wire.

* The correct way to insert the wire into the crimp connector

* Employing the correct crimp applications to crimp the connector

* How to implement warmth shrink accurately to the wire and crimp connector.

A nitinol wire/form memory alloy inchworm that walks across a table employing only warmth. The warmth is supplied by electrical existing heating up the skinny nitinol wire, causing it to return to its remembered form, a compressed coil in this scenario. A V-formed spring returns it to the commencing form.

Guidance RimstarOrg on Patreon https://www.patreon.com/user?u=680159

Subscribe for new films every single week http://www.youtube.com/user/rimstarorg?sub_affirmation=1

Go to the principal channel webpage below https://youtube.com/rimstarorg

See also:

How to Make Nitinol Wire Inchworm (Shape Memory Alloy)

https://www.youtube.com/look at?v=getfzfZJjHM

Nitinol Wire – How to Use it

https://www.youtube.com/look at?v=4Yi4epJ83EE

How a Rocket Performs/Earth to Area Eg SpaceX Falcon 9 and Dragon

https://www.youtube.com/look at?v=L0AMQ6kRNMA

My webpage about this nitinol wire inchworm:

http://rimstar.org/science_electronics_tasks/nitinol_wire_inchworm_form_memory_alloy_handmade.htm

Adhere to at the rear of-the-scenes on:

Twitter https://twitter.com/#!/RimStarz

Google+ https://additionally.google.com/116395125136223897621

Fb https://www.fb.com/rimstarorg

http://rimstar.org

The inspiration came from this one:

https://www.youtube.com/look at?v=DW4WaTmoZ3c

Essence – audio by audionautix.com