Supply for Nickel Alloy Inconel 783 UNS R30783 for Swiss Manufacturer

We believe in: Innovation is our soul and spirit. Quality is our life. Customer need is our God for Supply for Nickel Alloy Inconel 783 UNS R30783 for Swiss Manufacturer, We sincerely welcome both foreign and domestic business partners, and hope to work with you in the near future!

HY 783 Material grades and equivalents

Inconel 783 / Alloy 783 / UNS R30783

An oxidation resistant low coefficient of thermal expansion (low CTE) superalloy developed for gas turbine applications.

The alloy is strengthened by a precipitation-hardening heat treatment made possible by additions of niobium and aluminum. In addition, the aluminum content provides excellent resistance to oxidation at high temperature.

The alloy’s density is 5% less than those of superalloys such as INCONEL alloy 718. The combination of low expansion, high strength and excellent resistance to oxidation makes the alloy especially useful for gas turbine and steam turbine components.

The low expansion enables closer control of clearances and tolerances for greater power output and fuel efficiency.

Table 1 - Limiting Chemical Composition*, %

Chromium……………………………………………………………. 2.5-3.5

Nickel ……………………………………………………………….26.0-30.0

Iron ……………………………………………………………………24.0-27.0

Niobium…………………………………………………………………2.5-3.5

Aluminum………………………………………………………………5.0-6.0

Cobalt………………………………………………………………Remainder

Boron……………………………………………………………..0.003-0.012

Carbon………………………………………………………………0.03 max.

Manganese………………………………………………………..0.50 max.

Silicon……………………………………………………………….0.50 max.

Phosphorus……………………………………………………..0.015 max.

Sulfur ……………………………………………………………….0.005 max

Titanium…………………………………………………………………0.1-0.4

Copper……………………………………………………………….0.50 max

Physical Properties

Table 2 - Physical Constants

Density, g/cm3…………………………………………………………..7.81

lb/in3………………………………………………………….0.282

Melting Range, °F ……………………………………………..2437-2565

°C …………………………………………….1336-1407

Specific Heat, Btu/lb•°F (77°F)……………………………………0.109

J/kg•°C (25°C)……………………………………….455

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

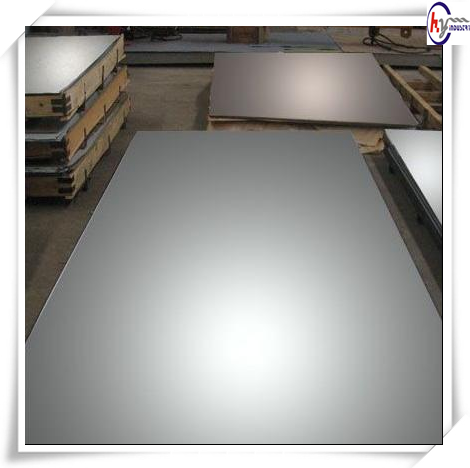

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

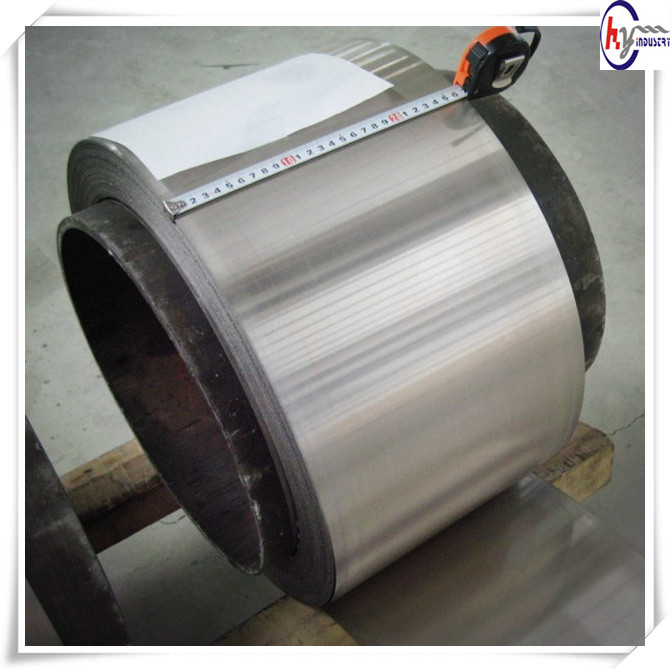

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

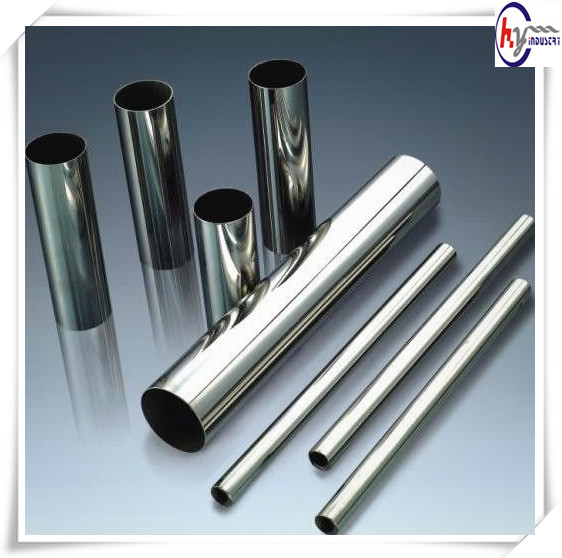

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

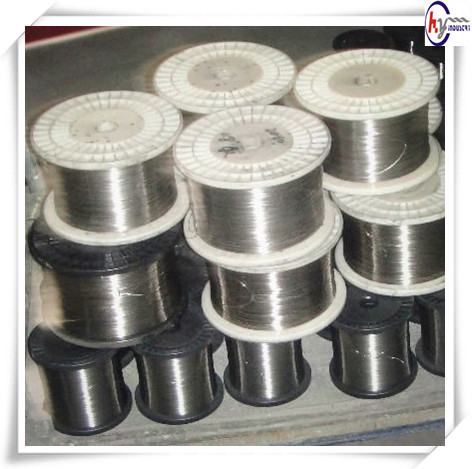

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

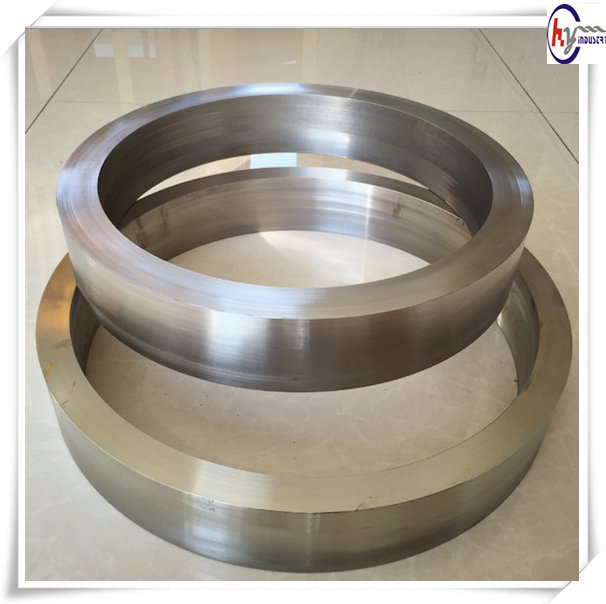

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Supplier foil、strip、sheet、coil、plate、wire、rod、bar、tube、pipe、flat ribbon、Profiled wire…

BuildingNo.1,Third Industrial District XiTou Village SongGang Town Bao’An District ShenZhen City GuangDong Province China

Substantial Temp Nickel Centered & Tremendous Alloys – Mechanical Homes Inconel Round Bar, Plate Sheet Offer – Inconel is designed of Mostly Nickel and a number of other aspects. The origin coming from Supernovas. Inconel is a Tremendous Alloy and Michlin Metals sells Inconel Round Bar, Hex Bar, Flat Bar, Plate, Sheet, Tube and Pipe.