Wholesale Price Titanium alloy 6Al-4V ELI UNS R56401 Supply to Istanbul

The company upholds the philosophy of "Be No.1 in quality, be rooted on credit and trustworthiness for growth", will continue to serve old and new customers from home and overseas whole-heatedly for Wholesale Price Titanium alloy 6Al-4V ELI UNS R56401 Supply to Istanbul, sincerely look forward to serving you in the near future. You are sincerely welcome to visit our company to talk business face to face with each other and establish long-term co-operation with us!

HY Titanium 6-4 ELI Material grades and equivalents

6-4 ELI Titanium, 6-4 ELI, UNS R56401

Introduction

Low interstitial version of HY Titanium 6-4 ELI, for maximum toughness. Preferred for marine and cryogenic applications. This grade is normally used in the annealed condition. HY Titanium 6-4 ELI is the preferred choice for the medical implant field.

Stress relief 900-1200°F 1 to 4 hours, air cool. Duplex anneal, bar and forgings: Solution anneal 50-100°F below the beta transus, hold 1 hour minimum, air cool. Then reheat within the range 1300-1400°F, hold 1 hour minimum, air cool. Stress – relief annealing is performed after welding.

Chemistry Composition

|

Al |

V |

Fe |

O |

C |

N |

H |

Y |

Others, |

Others, |

Ti |

|

|

MIN |

5.5 |

3.5 |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

MAX |

6.5 |

4.5 |

0.25 |

0.13 |

0.08 |

0.03 |

0.0125 |

0.005 |

0.1 |

0.4 |

Balance |

Features

Resistant to bodily fluidsResistant to a variety of corrosive environmentsFreedom from chloride stress corrosion crackingGood strength and toughness over a wide temperature rangeHigh resistance to erosion corrosion and corrosion fatigueUseful resistance to dry chlorine, fluorine, hydrogen chloride and hydrogen fluoride gases

Applications

Medical and dental implantsCryogenicsAerospaceChemical processing

Physical Properties

Density: 0.160 lb/in3

Melting Range: 2370 – 2460°F

Beta Transus: 91790+25°F

Minimum Tensile Properties, AMS 4919, Duplex Annealed

|

Temperature, °F |

68-212 |

68-600 |

68-1000 |

68-1200 |

68-1500 |

|

Coefficient* of Thermal Expansion, in/in°F x 10-6 |

9.18 |

9.54 |

10.08 |

10.44 |

10.8 |

Mechanical Properties

Typical hardness Rockwell: C 30-34 Specific minimums, AMS 4931, bar and forging

Representative Tensile Properties, Sheet

|

Diameter, in |

< 3.0 |

< 3.0 < 4.0 |

< 4.0) < 6.0 |

|

Tensile Strength, ksi |

125 |

123 |

120 |

|

0.2 % Yield Strength, ksi |

115 |

110 |

110 |

|

Elongation, % *L (**ST) |

10 (8) |

10 (8) |

8 (8) |

|

Reduction of Area, % *L (**ST) |

25 (–) |

20 (15) |

15 (15) |

* Longitudinal ** Short Transverse

Typical Elevated temperature Properties

|

Temperature, °F |

93 (200) |

149 (300) |

204 (400) |

260 (500) |

|

Ultimate Tensile Strength, ksi |

843.3 (121) |

772.2 (112) |

723.9 (105) |

657.7 (98) |

|

0.2 % Yield Strength, ksi |

710.2 (103) |

641.2 (93) |

586.1 (85) |

531.0 (77) |

|

Elongation, % |

13 |

15 |

16 |

16 |

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

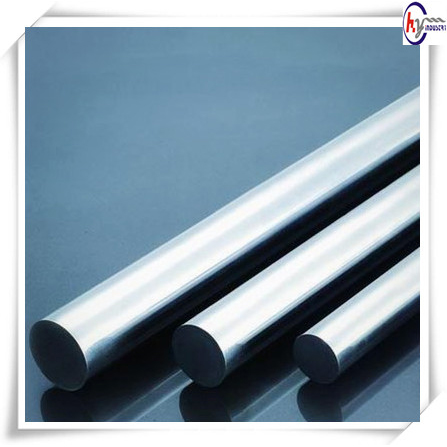

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

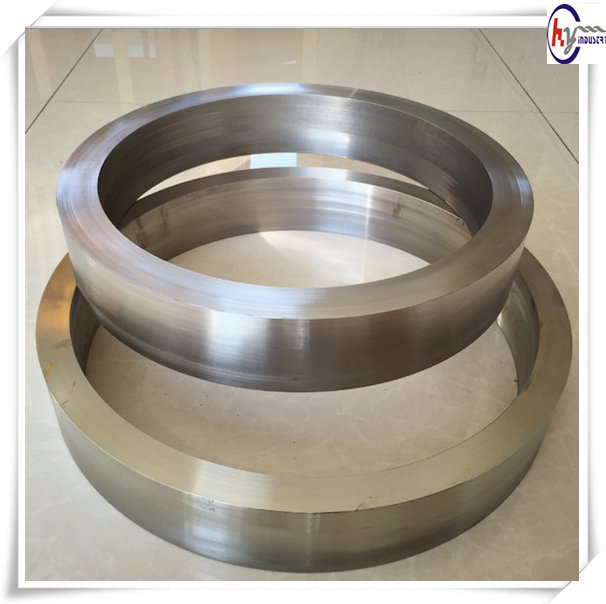

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Turning insert brochures are obtainable for obtain at http://www.mitsubishicarbide.com/mmus/en/products/catalog/turning.html

Mitsubishi offers particular J-Series breakers and micro-grain grades for turning hard to minimize supplies. Mitsubishi breakers for warmth resistant alloys include the FJ (mild slicing), MJ (medium slicing) and GJ (medium to semi-weighty slicing). The presenting is concluded with the addition of the twin rake MS (medium slicing) breaker and spherical RCMX insert also for medium slicing. FJ and MJ collection insert are obtainable in G Class tolerances for applications that need a sturdy sharp slicing edge. For Titanium and non-ferrous supplies, the polished FJ-P/MJ-P edition is obtainable.

The FJ’s sharp slicing geometry is obtainable in common .002, .004, .008 and .016″ software nose radius. Although the MS and MJ software nose radius begins at .016 and the GJ at .031″ and up. Our warmth resistant alloy breakers are obtainable in a vast range of micro-grain grades particularly design for this market place phase. Our micro-grain grades are obtainable non-coated or topped off with PVD/CVD coatings and edge preparations to suit to the insert software range.

Out there uncoated grades are: RT9005, RT9010, TF15 and Hti10.

Our Miracle Coating (Al, Ti)N PVD grades are: VP05RT, VP10RT and VP15TF.

CVD coated US905 is design to deliver unequalled dress in resistance in stable higher velocity applications. The close microstructure of US905 CVD coatings limits insert flank and deal with dress in at higher speeds when in contrast to other merchandise. US905 has the best hardness cemented carbide substrate appropriate for CVD Coating.

To see all Mitsubishi Cutting Device products channels on YouTube, comply with url:

http://www.youtube.com/user/mitsubishicarbide/video clips?view=one

Or

Go to 1 of our products precise channels below:

The Cutting Edge: http://www.youtube.com/playlist?list=PL1CEA67C978F3029D&feature=view_all

Turning & Dull Channel: http://www.youtube.com/playlist?list=PL0D406ECCFFF53995&feature=view_all

Milling Channel: http://www.youtube.com/playlist?list=PL648BF1B051AE20F0&feature=view_all

Drilling Channel: http://www.youtube.com/playlist?list=PL6960075BD195101A&feature=view_all

Grooving Channel: http://www.youtube.com/playlist?list=PL3AD4CC3127719A38&feature=view_all

Swiss Tooling Channel: http://www.youtube.com/playlist?list=PL0FBAAF2F0230343C&feature=view_all

CBN Channel: http://www.youtube.com/playlist?list=PLBB88F97F9A2B5376&feature=view_all

Strong Carbide Close Mill Channel: http://www.youtube.com/playlist?list=PL7A1549BEF477EDDB&feature=view_all

Mitsubishi Elements Usa – Cutting Applications, Social Media Websites:

Fb: http://www.facebook.com/MitsubishiMaterials.US.CuttingTools

Twitter: http://twitter.com/#!/MMUSCuttingTool

YouTube: http://www.youtube.com/user/mitsubishicarbide

Supplemental Means:

Encounter Mitsubishi Carbide’s Patented On the internet Catalog with downloadable CAD information http://www.mitsubishicarbide.internet/mmus/en/catalogue/index.html

Extra Mitsubishi Cutting Device Films can be discovered at http://www.mitsubishicarbide.com/mmus/en/products/online video/index.html

Issues remember to speak to:

Complex Guidance at one-800-486-2341

Or

E mail MarketingServices@mmus.com

Protected specialized inquires can be submitted to Mitsubishi Elements at https://www.mitsubishicarbide.com/mailform/mmus/en/literature/sort.html

Thank you for using the time to view this online video and remember to take a look at Mitsubishi Elements Usa at http://www.mmus.com

I am earning my own wedding day band from Inconel X-750 just to be diverse. The material is a agony to do the job with thanks to the superior nickel/chromium articles. The lathe is a LeBlond “dual generate” with an Aloris-copy device article. I built an adapter for the one.25″ boring bar socket to sleeve it down to a 5/8″ side-lock drill shank. I utilised an indicator to sweep the device holder, inserting it instantly on center. The drill is a Seco CrownLoc As well as with .625″ tip, running at around 80sfm, hand feed with plenty of stress, and drenched in reducing oil (not demonstrated in pic). Chips had been astonishingly limited of course, I had to withdrawal the device numerous moments to eliminate chips, due to the fact they weren’t becoming flushed by coolant.