18 Years manufacturer Nickel Alloy Incoloy 925 UNS N09925 for Ukraine Factories

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for 18 Years manufacturer Nickel Alloy Incoloy 925 UNS N09925 for Ukraine Factories, winning customers' trust is the gold key to our success! If you are interested in our products, please feel free to visit our web site or contact us.

Y925 Material grades and equivalents

HY 925 /UNSN09925

HY 925 Chemical compostion:

|

Alloy |

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

Cu |

S |

Al |

Ti |

P |

Mo |

|

HY 925 |

Min. |

42 |

19.5 |

bal |

1.5 |

0.15 |

1.9 |

2.5 |

|||||

|

Max. |

46 |

23.5 |

0.03 |

1 |

0.5 |

3 |

0.03 |

0.50 |

2.4 |

0.03 |

3.5 |

HY 925 Physical properties:

|

Density |

8.14 g/cm3 |

|

Melting point |

1343 ℃ |

HY 925 minimum mechanical properties in the roomtemperature

|

Alloy state |

Tensile strength |

Yield strength RP0.2 N/mm² |

Elongation A 5 % |

|

Solution treatment |

650 |

300 |

30 |

HY 925 Characteristic as below :

This is an age-hardenable alloy of nickel-chromium-iron. The additions of titanium and aluminum enable it to be age-hardened while molybdenum and copper contents enhance resistance to corrosive media. Designed primarily for applications in the production of gas.

HY 925 Application field:

It is used in the petroleum industry for applications such as gas well components, valves and tubing, as well as finding use in high-strength piping systems.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

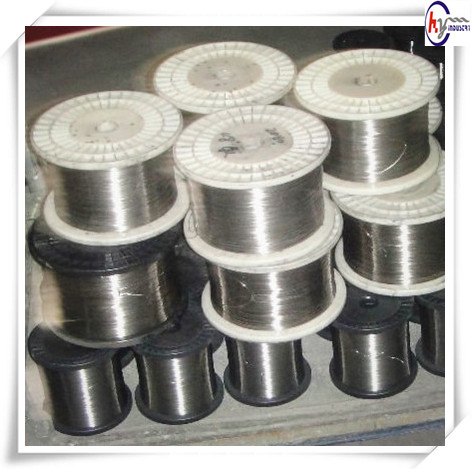

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

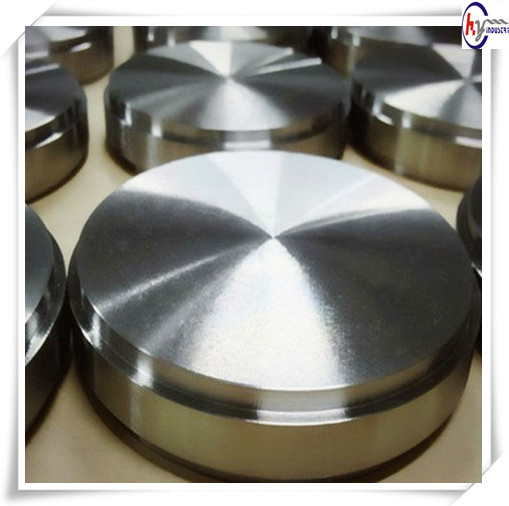

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Substantial Temp Nickel Centered & Tremendous Alloys – Mechanical Homes Inconel Round Bar, Plate Sheet Offer – Inconel is designed of Mostly Nickel and a number of other aspects. The origin coming from Supernovas. Inconel is a Tremendous Alloy and Michlin Metals sells Inconel Round Bar, Hex Bar, Flat Bar, Plate, Sheet, Tube and Pipe.

http://www.shelmetcastings.com

Get a Totally free Process Suggestion. Get in touch with 920-622-3344

How to locate a reputable expense caster – Getting a reputable expense caster is just not normally straightforward. Look for people who have been in organization a very long time. Look for issues like the ISO seals, due to the fact when expense casters are adhering to the ISO 9000 technique they have committed to a high quality plan. A high quality plan generally suggests you have a reputable caster. Shelmet Financial investment Casting Enterprise, Inc, has been in organization for around 55 a long time and we are ISO 9008 qualified which is portion of the ISO9000 technique. Shelmet Precision Casting, Inc is at the moment evaluating and expecting acceptance on the ISO2015 update. We feel that we are one of the ideal expense casters in the field. Why do we feel that? Simply because we reside it just about every working day. American Manufactured.

Experienced precision casting expense foundries like Shelmet Precision Casting, Inc, generate a selection of metal castings in sizes from fractions of an ounce to 20 kilos or more. Various varieties of expense casting and precision casting have dated again a couple of hundreds of a long time. Pretty much the exact methods of melting metals, producing easy dies for numerous instances, and producing the finished metal casting utilised really comparable tactics very long ago. Remarkably in depth castings make expense castings the ideal decision for manufacturing finished metal castings often generated from various alloys. Artworks of copper and bronze and even gold ended up created using precision casting tactics, due to the fact these metals and easy metal alloys ended up more conveniently available.

Wax Place: sample waxes, soluble waxes, specialty waxes, wax reclamation and recycling products, wax sample cleaner and sample wetting remedy

Refractories: fused silica, tabular alumina, fused brown alumina, alumina silicates, molochite, white alumina, sand & flours, zirconia, plaster, fiber increased refractories and carbon stucco

Binders: binders, silica, gravity chart, wetting agents and other additives

Crucibles: crucibles and pour cups

Metals: scrap and copper, brass, metal, nickel, cobalt and other alloys

Of system each individual casting business will have their very own distinct combinations of casting machines, based on the varieties of metals and alloys they focus in and on regardless of whether their concentration is expense casting, die casting, sand casting or other casting functions.

Remember to call Shelmet Precision Casting for all your casting demands. http://www.shelmetcastings.com

Get a fast estimate now: 920-622-3344

Alloys: three hundred Series Stainless Metal, Aluminum Alloys, Carbon & Lower Alloy Steels, Cobalt Base Alloys, Gray Iron, Nickel Base Alloys (airmelt), Precip. Hardening St. Metal (seventeen-4PH,fifteen-5PH), four hundred Series Stainless Metal, Copper Base Alloys, Device Steels

Some big industries that use Shelmet Precision Castings, Inc:

Agricultural Machinery

Health-related Devices

Foodstuff Processing Devices

Valve and Hydraulics

Electrical Distribution

Waste and Water Therapy Devices

Paper Production and Processing

Mining Devices

Marine Fittings

Financial investment casting machines is the spine of just about every metal casting method. Financial investment casting machines can be divided into two groups, consumables and genuine machines. Devices by itself can be divided by place: wax place, shell place, foundry, ending place and software place. The consumables can be divided by variety: waxes, refractories, binders, crucibles and metals.

How the Aerospace field works by using expense castings?

How to Ask An Expert at No Charge for Your Financial investment

Casting Tasks?

Advantages of etching your expense castings?

How to get no cost method recommendations for your

expense casting projects?

How to Conserve with Financial investment Casting?

How to get the job done with numerous suppliers in Precision Casting?

When to USe Teflon Coating?

Why Anodize a Metallic Casting?

Why Plate a lost wax casting?

Main Products: Aerospace, Architectural Components, Diesel Engines, Firearms, Foodstuff Processing, Typical Vehicles/Tractors, Industrial Fuel Turbines, Marine Purposes, Army Components, Pumps/Valves, Sporting Products, Automotive, Typical Field, Health-related Devices

Financial investment casting parts and structures have substantial toughness and mechanical houses, and are rarely vulnerable to worn out exhaustion. The mechanical houses and micro-structure of the alloys can be conveniently controlled by the location time, as quick cooling tactics produce outstanding toughness casting parts. Financial investment Casting Devices – Metal Financial investment Castings – Shed Wax Castings – All Preferred Metallic Casting Alloys

Shed wax casting

As Found on FOX Company Information with John Criswell, Production Marvels

The manufacturing method will assist you in the genuine mechanical layout. Shed wax casting is the method exactly where a metal alloy is solid from layout prototype.

Latitude-Longitude: forty four.16993,-89.247591

Shelmet Precision Castings, Inc.

http://www.shelmetcastings.com

Get a fast estimate now. Get in touch with 920-622-3344