One of Hottest for Iron Alloy Precision Alloy 1J50 Factory in Rwanda

We have a highly efficient team to deal with inquiries from customers. Our goal is "100% customer satisfaction by our product quality, price & our team service" and enjoy a good reputation among clients. With many factories, we can provide a wide range of One of Hottest for Iron Alloy Precision Alloy 1J50 Factory in Rwanda, If you are interested in our products, please feel free to send us your inquiry. We sincerely hope to establish win-win business relationships with you.

HY J50 Material grades and equivalents

1J50 / JIS PB

HY J50 Chemical composition

|

Grade |

C |

P |

S |

Mn |

Ni |

Si |

Mn |

Cu |

Fe |

||||

|

≤ |

|||||||||||||

| HY J50 |

0.03 |

0.020 |

0.020 |

0.3-0.6 |

49.5-50.5 |

0.15-0.30 |

0.30-0.60 |

≤0.20 |

Rest |

||||

HY J50 Alloy Mechanical properties in the room temperature

|

Grade |

Shape |

Magnetic properties |

|||

|

Initial permeabilityμO |

Maximum permeabilityμm |

Hc |

Saturation induction density BS |

||

|

HY J50 |

Cold rolling strips |

≥3.8 |

≥62.5 |

≤9.6 |

1.5 |

|

Forging bar |

≥3.1 |

≥31.3 |

≤14.4 |

1.5 |

|

HY J50 Characteristic as below

The HY J50 has rectangular hysteresis loop and high saturation magnetic induction, is mainly used to worked at a moderate magnetic field magnetic amplifier, choke ring, rectifier circle, as well as the computer device components.

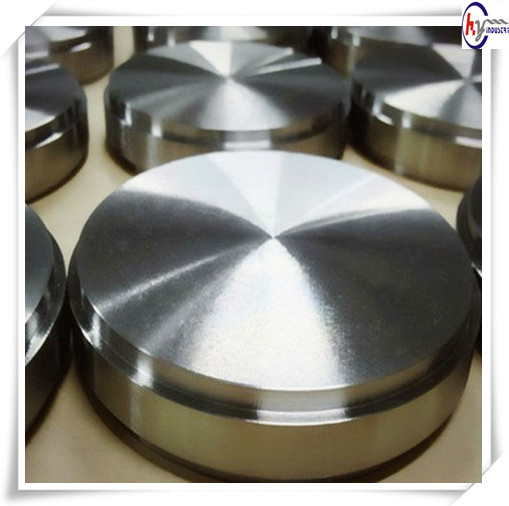

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

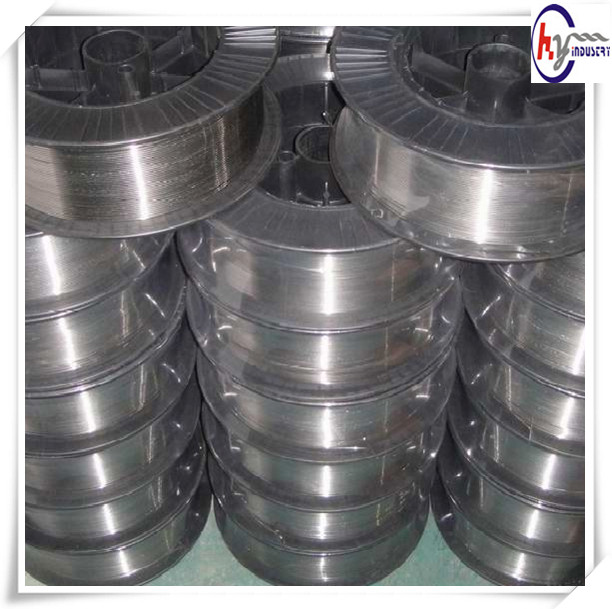

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

To comprehend that the utilizes for particular metals relate to their unique qualities.

To comprehend that the qualities of metals can be improved by generating alloys.

To recall that some of the hottest alloys, called ‘Smart Alloys’ can change their qualities on demand from customers.

Duplicate the table beneath. Working with a companion, entire as a great deal of the table as you can.

Very low density, powerful, resistant to corrosion, very good conductor of energy

Good conductor of energy, resistant to corrosion, quickly formed, flexible

Shiny, very resistant to corrosion, very unreactive, soft, quickly formed

Extremely powerful, very dense.

Lightweight buildings, plane, drinks cans, higher voltage cables.

Electrical wiring, h2o pipes.

Jewelry.

Substantial buildings and significant responsibility engineering these as bridges, trains, autos and so forth.

In pure metals the atoms prepare them selves closely collectively into regular styles. This tends to make them dense and also presents them numerous of their other helpful qualities.

The layer arrangement of the atoms permits the metals to transform form if a pressure is utilized. The layers can slip around every other.

This can be helpful if you want to form the steel but not so helpful if you want it to resist the pressure and be powerful.

By mixing two or additional metals collectively the regular arrangement of the atoms is disrupted. This stops the atoms forming layers and tends to make it harder for the atoms to slide around every other. The alloy is more robust than the pure metals.

Steel B

Steel A

Steel is an alloy. Pure iron is not powerful enough to be employed in buildings. Steel contains a smaller amount of carbon. This disrupts the layers of atoms in the steel and improves the toughness of the steel considerably.

Despite the fact that it is very powerful metal will corrode (rust) quickly and it has to be regularly protected from the consequences of h2o and air.

Stainless metal is an alloy that contains other metals these as Nickel and Chromium. Stainless metal has the toughness of metal mixed with the corrosion resistance of nickel and the shininess of chromium. This tends to make it a helpful materials in programs exactly where you will need toughness mixed with magnificence and corrosion resistance..

Clever Alloys

These are alloys that can ‘remember’ their primary form. If they are deformed they can return to their primary form.

Condition memory glasses

Condition memory Stent to continue to keep a blocked blood vessel open

Metals, Alloys and Clever Alloys

Finding out Objectives:

To comprehend that the utilizes for particular metals relate to their unique qualities.

To comprehend that the qualities of metals can be improved by generating alloys.

To recall that some of the hottest alloys, called ‘Smart Alloys’ can change their qualities on demand from customers.

The progress of improved metallic resources is a crucial action at the leading edge of science and know-how. Metals offer unrivalled mixtures of houses and reliability at a cost which is economical. They are adaptable mainly because subtle improvements in their microstructure can cause dramatic variations in their houses. For illustration, it is feasible to purchase business steel with a energy as lower as 50 MPa or as large as 5500 MPa. They can be built with a microstructure which is finer than that of carbon nanotubes. An understanding of the progress of microstructure in metals, rooted in thermodynamics, crystallography and kinetic phenomena is crucial for the resources scientist. The bulk of the 1.4 billion tonnes of metals made annually are the outcome of developments within just the last 10 a long time

http://www.msm.cam.ac.british isles/phase-trans/2002/creep.1.html